The Company

Renault, a trailblazer in the automotive sector, has been revolutionizing mobility for over a century. Established in 1899 by Louis Renault in France, the company has consistently pushed the boundaries of innovation, driving the industry forward with sustainable technologies and solutions.

At its core, Renault’s business model revolves around delivering an expansive array of automotive products and services. The group boasts a broad range of vehicles tailored to meet the diverse preferences of their clientele.

In this article, we will delve into the transformation journey of Renault’s dealerships and workshops, fostering a culture of continuous improvement, and shed some light on the outcomes achieved.

Renault and Continuous Improvement

Over the years, Renault has acknowledged continuous improvement as a pivotal force in propelling both innovation and process improvement. The company has embraced this philosophy at different levels of the organization and in various departments and areas.

Implementing a culture of continuous improvement has allowed Renault to optimize operations, striving for excellence across the whole business and engaging its entire workforce in this process. As a result, Renault has reaped a plethora of positive outcomes.

This article will delve into the strategies and initiatives championed by Renault’s dealerships and workshops in France and share the results achieved thanks to the CI approach. Join us on this journey focusing on the after-sales transformation, seeking operational excellence and increased customer satisfaction.

The Approach

Since 2019, the Kaizen Institute has supported Renault’s quest for continuous improvement. Today, over 170 French dealerships are using KAIZEN™️ methodologies in their after-sales services. Find out more about the KAIZEN™️ initiatives rolled out and the results achieved.

Daily KAIZEN™ – Streamlining Team Management

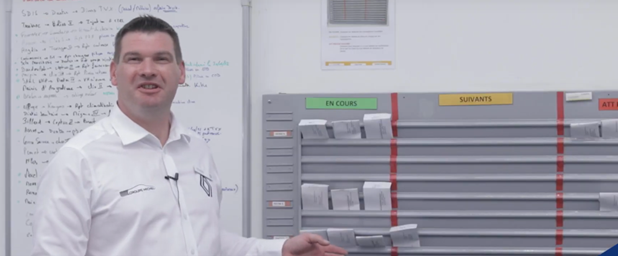

Daily KAIZEN™ is an approach that provides leaders with the tools to manage and organize their teams day after day effectively. The aim is to ensure alignment between performance and objectives, enhance responsiveness to deviations, and optimize the time spent discussing improvement opportunities.

This approach includes regular meetings between leaders and their teams. Performance metrics, work planning, and team improvement activities are reviewed during these sessions. A table is used to present this information.

At Renault dealerships, this sharing ritual happens every morning, lasting approximately five minutes and marking the day’s onset. Priorities, workshop quality, and performance are the central topics of discussion. These meetings do evolve over time, constantly improved based on team insights.

Within the dealerships, the team board houses information such as the quality and communication plan, daily plan, and vehicle tracking, among other relevant data. Quality metrics and business volume are closely monitored, coupled with 5S and an action plan.

Implementing Daily KAIZEN™ has resulted in a significant transformation. Communication between the customer-facing front office team and the production-oriented back office improved significantly. All employees also had a greater awareness of the activities carried out in the workshop.

Realigning the flow of information between various departments was also a focal point, resulting in more transparent communication about tasks at hand and improved task monitoring.

Overall, the rollout of Daily KAIZEN™ at Renault has made a substantial impact, championing continuous improvement and fostering a more efficient and collaborative work culture.

Upselling – Encouraging Additional Sales

In a fiercely competitive market, customer loyalty is paramount. To achieve this, meeting client expectations and anticipating their needs is essential. They offer solutions to issues that clients might not have considered but ensure the proper maintenance of their vehicles benefits both the customer and dealership. The need for this workshop arose during the KAIZEN™️ diagnosis, sparking a focus on upselling.

Upselling initiatives involve inspecting vehicles using a checklist, emphasizing specific elements like tires, rims, windshields, and the overall body condition. The customer reviews the proposed course of action for the vehicle, deciding whether to proceed with additional tasks.

Since launching this workshop at the Renault Issoire dealership, the average basket value has surged from €328 to €382 – a €50 increment per customer. The “Challenge Performance Atelier,” a quarterly challenge set by the manufacturer to boost parts sales at dealerships, witnessed a 140% hike since 2019, thanks to mechanics’ dedication to inspecting vehicles.

Front-Back – Organizing the Front-Back and Leveling the Workload

Delivering excellent service requires meticulous attention to customers and their vehicles. The receptionist’s role is crucial in managing the customer’s journey, from vehicle reception to return, ensuring a methodical, courteous service aligned with the manufacturer’s standards. Meanwhile, the production manager needs to oversee workshop planning, ensuring both the set deadlines and work quality are met.

At the Renault Angoulême dealership, following a diagnostic phase with the local team, the reception area showed apparent signs that it needed reorganization. The workload was unevenly distributed throughout the day. Implementing this workshop balanced morning and afternoon appointments at consistent 15-minute intervals. The tracking of work progress by receptionists did not match actual progress, impacting quality, as customers were not timely informed about delays, if any.

To ensure an adequate workload, the appointment load potential was updated. A loading board was introduced, allowing a quick and clear view of the available mechanics. Additionally, a visual loading board was created, giving a rapid glance at availability to work with the vehicles on a given day. This board is complemented by another one indicating the work status. Both are updated throughout the day by the Production Manager, allowing the receptionist to keep clients informed about their vehicle repair status.

The front-back organization workshop not only optimized workload and deadlines but also enhanced productivity by 4 points and improved client satisfaction (NPS) by 4 points.

Parking Organization – Optimizing Parking Areas

Parking can be a source of customer stress and a productivity drain for employees. In this sense, having a well-organized car park at the dealers is essential. After the KAIZEN™️ diagnosis at the Renault Calais dealership, improvement opportunities were identified in terms of time savings for teams, parking accessibility, and enhancing customers’ well-being.

Straightforward solutions were devised: sizing the number of parking spots based on service (mechanics, Renault Minute, bodywork, new and used vehicles) based on the number of customers per day and tagging vehicles and key holders with service-specific colored cards. This system allows for swift identification of a vehicle’s designated service.

Following the workshop’s implementation, locating keys and parking became effortless, resulting in time savings. Optimizing parking areas yielded significant benefits, including enhanced efficiency, improved work time, and decreased customer and employee parking-related insatisfactions.

Standardization – Streamlining Processes to Enhance Client Experience

Ensuring process consistency and stability is paramount for any organization. Standards uphold consistency, serve as benchmarks for identifying deviations, ensure knowledge preservation, facilitate team training and versatility, and form the foundation for audits.

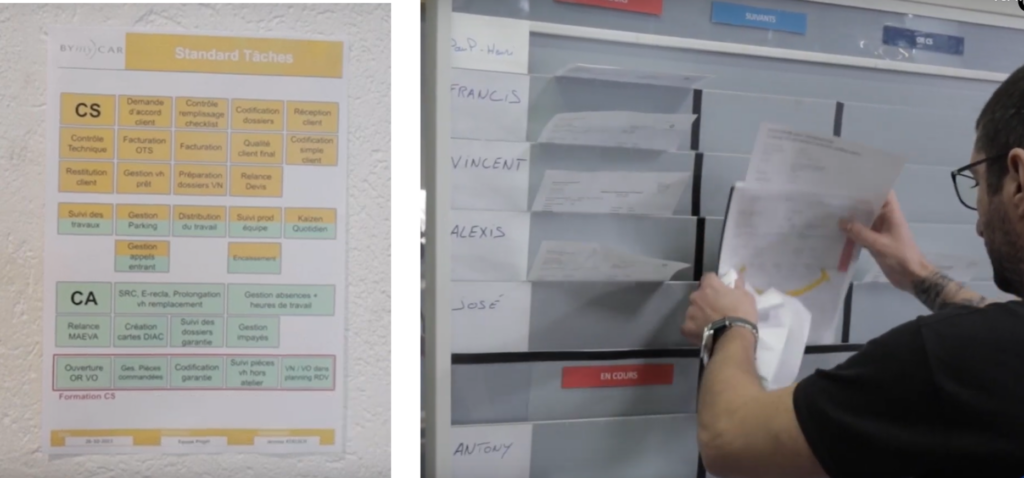

With the introduction of KAIZEN™️ at the Renault Verdun dealership, one of the first improvements was employing a load board to monitor processes. A tool was also designed to track mechanics’ productivity, allowing them to view their daily productivity, along with the team’s, during the Daily KAIZEN™ session and track their monthly progress. Every tool developed comes with a standard to make it easy to use.

After a 12-month follow-up, the indicators skyrocketed: productivity soared by 22 points, the average basket increased by €111, and the Net Promoter Score (NPS) rose by 10 points compared to the previous year. These positive outcomes underline the significance of standardization in process improvement and achieving great results.

Quality – Promoting Excellence

Ensuring quality at every step of the customer journey — a process outlined by Renault’s standards — is imperative. During the diagnostic phase at the Renault Saint-Etienne dealership, a significant improvement opportunity was identified due to the non-compliance with the standards set for the customer journey. This was adversely impacting the workshop’s NPS score.

To address this, reimplementation and consistent monitoring of the customer journey standards were reintroduced into the daily tasks of the receptionists. Subsequently, a checklist was created to embed quality controls, ensuring they are applied to all the mechanical interventions.

The customer journey steps were tailored for the Saint-Etienne dealership using Renault’s standards. A designated parking area was established for customer reception, ensuring they always find a spot upon arrival. Quality control was also reinforced through a checklist completed by the employee responsible for vehicle cleaning, guaranteeing that vehicles are returned in pristine condition.

Key performance indicators showed significant progress, especially the NPS score, which surged by 23 points in 12 months, moving from 56 to 79. The rate of return visits due to complaints plummeted by 50%. Such outcomes show the positive impact of the KAIZEN™️ improvement project on the quality of services the dealership offers.

“Jockey” – Efficiently Allocating Resources

In an ever-evolving sector, organizational stability and efficiency are paramount. Hence, maximizing the added value of specialized/technical labor by focusing on core tasks is essential. Introducing a team member to handle non-technical yet crucial duties proves advantageous. This employee is part of the after-sales team and is managed by the production manager.

Upon initial assessment, a substantial loss of time was noticed in vehicle preparations and tasks undertaken by mechanics, electromechanics, and cotech technicians. Implementing the “jockey,” responsible for non-technical duties (like cleaning the vehicle and managing its movements within the dealership’s boundaries), enabled freeing up the technical workforce for high-value tasks. This shift was well received, leading to productivity gains and customer satisfaction.

Implementing this workshop allowed mechanics and technicians to focus on critical tasks, boosting their capacity to service more vehicles daily and ensure timely completion. This strategy led to a 9-point surge in productivity, a 17% revenue increase, and a 25% drop in return visits at the Renault Dijon mechanical workshop.

Workload Planning – Maximizing Planning Efficiency

The efficient operation of a workshop is directly linked to its management, taking into account the technical diversity of operations. Understanding the capacity of each specialization is key, and planning should be accessible, visible, and depicted on a dynamic physical or digital board.

During the diagnostic phase at the Renault Courbevoie dealership, workload planning issues were identified, especially in the highly technical areas. Teams grappled with challenges like workload surges, leading to customer dissatisfaction and communication barriers between the front and back-office teams. To address these issues, the workload board was redesigned to foster communication across both teams. The customer appointment load was redefined based on intervention types to prevent team overloads. Vehicles were color-coded, denoting whether they were being worked on (green), awaiting approval (red), or had parts waiting to arrive (blue). Additionally, color codes were used to track progress and update customers in real time.

These improvements resulted in significant benefits for the Renault Courbevoie dealership, including a 5% rise in team productivity, a 7% increase in vehicles serviced, and a 10% quality boost. The improvements helped establish a robust workshop structure, better communication across different departments, involve all employees, and, most importantly, escalate productivity and customer satisfaction.

Pre-picking – Optimizing Order Preparation

Typically, the workshop stands as the dealership store’s primary client in terms of volume, loyalty, and transportation cost savings. Consequently, synergy between services is vital for seamless operations. Delays in preparation and part unavailability lead to time losses for staff, customer service delays, revenue reduction, and even dissatisfaction. Adequate anticipation and planning increase business, efficiency, staff comfort, and a more gratifying customer experience. Pre-picking plays a pivotal role.

Pre-picking is an advance order process for parts. This system was introduced to correct out-of-stocks in the workshop and communication gaps between the warehouse and the workshop.

In the project’s initial phase at the Renault Marmande dealership, 10 columns were established, each associated with a number from 0 to 9. Every advanced parts preparation was placed in a box, labeled with the repair order number. The last digit corresponds to the column where the box was positioned. Additionally, to ensure there are no parts swaps or anyone taking the wrong box, each carries a copy of the warehouse request, quickly identifying parts linked to the repair order.

In the subsequent phase, carts containing ordered parts were prepared and adjusted by pickers when needed. This approach distributed their workload throughout the day, fostering greater flexibility and warehouse organization enhancing staff comfort. Furthermore, the box system eases order tracking and upselling by increasing parts availability. Production teams also save time every day as they no longer wait for parts preparation and delivery. The boxes are placed in the warehouse, next to their workstations.

In a nutshell, implementing pre-picking at the Renault Marmande dealership significantly reduced mechanic wait times, anticipated stock shortages, and enhanced customer satisfaction. It fostered better organization, communication, and cooperation between the store and workshop, resulting in substantial quality and revenue gains.

5S Workshop – Organizing Workspaces

The 5S is an approach to manage and organize the workplace. They consist of a set of five steps, with each “S” denoting a Japanese term associated with organization and discipline: SEIRI (Sorting), SEITON (Set in order), SEISO (Shine), SEIKETSU (Standardize), and SHITSUKE (Sustain). The 5S became one of the KAIZEN™️ project’s primary focuses within Renault dealerships. The aim was to improve workstations, ensure work quality and efficiency, and foster a better environment for employees and customers.

Implementing the 5S starts with a pilot. Later, the finalized model is planned for replication across the remaining workshop zones. A leader and a team are designated for each zone, with a set deadline for completing the 5S in stages. With this strategy, there is no need to halt production for an extended period to conduct a workshop, which should be part of the team’s daily routine.

Thanks to the collective commitment of the Renault Nantes Rezé dealership team, the 5S routine was consistently integrated into the company’s daily operations. The receptionists and the director also embraced the workspace organization concept.

Regarding the 5S implementation outcomes at this dealership, there was a reduced waiting time for borrowing tools amongst peers, parts exchanges, orders, and warehouse communication. Organization fostered efficiency in all employee’s daily tasks.

In summary, the 5S implementation significantly impacted the quality, efficiency, and motivation of the employees. A continuous commitment to the 5S as a daily practice ensures these benefits endure over time.

Results

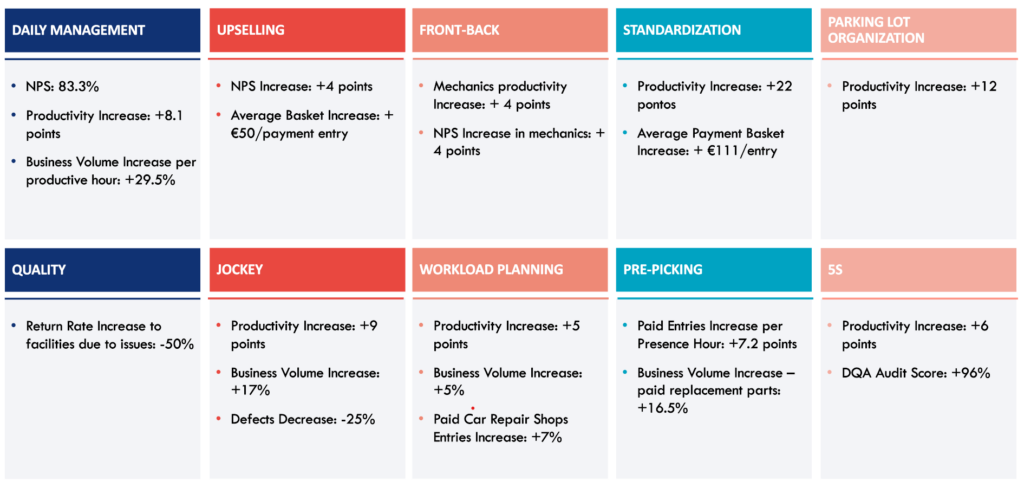

The KAIZEN™️ project yielded considerable quality, efficiency, and customer satisfaction improvements. Renault optimized its operations by adopting a philosophy of continuous improvement within its dealerships, propelling excellence throughout every business aspect.

Here are some quantifiable results achieved by the Renault dealerships and workshops mentioned in this article, throughout their continuous improvement journey.

Daily Management

- Mechanical Workshop KPIs Evolution – Maintenance/Wear: 83.3% NPS

- Productivity Increase: +8.1 points

- Increase in Revenue per Hour: +29.5%

Upselling

- NPS Evolution: +4 points

- Average Basket Increase: + €50/transaction

Front-Back

- Mechanical Productivity Evolution: + 4 points

- Mechanical NPS Evolution: + 4 points

Parking Lot Organization

- Productivity Evolution: +12 points

Standardization

- Productivity Evolution: +22 points

- Average Basket Evolution: + €111/transaction

Quality

- Customer Return to Dealership Due to Issues: -50%

The “Jockey”

- Productivity Evolution: +9 points

- Business Volume Evolution: +17%

- Defects Evolution: -25%

Workload Planning

- Productivity Evolution: +5 points

- Business Volume Evolution: +5%

- Paid Workshop Entries Evolution: +7%

Pre-Picking

- Paid Entries per Hour of Presence: +7.2 points

- Business Volume – Paid Replacement Parts: +16.5%

5S Workshop

- Productivity Increase: +6 points

- DQA Audit Score: +96%

Conclusion

The KAIZEN™️ project within Renault’s dealerships and workshops in France led to significant improvements in quality, efficiency, and customer satisfaction. Renault and its dealership network acknowledged the significance of continuous improvement, incorporating this philosophy throughout the organization, with over 200 dealerships in France already rolling it out.

Through practices like Daily KAIZEN™️, Upselling, Front-Back Enhancement, Parking Lot Organization, Standardization, Quality Assurance, “Jockey” introduction, and Workload Planning Optimization, Renault streamlined operations and fostered a more efficient, collaborative work culture.

The initiatives resulted in tangible improvements including better productivity, high average sales figures, improved NPS, and expanded business volume. Moreover, there was a decrease in customer complaints, loss of time, and operational failures.

The KAIZEN™️ project within Renault’s dealerships and workshops in France showcased its potential to achieve excellence, increase service quality, escalate operational efficiency, and amplify customer satisfaction. Renault will keep embedding continuous improvement into its organizational fabric, championing excellence across all operational areas.

See more on Operations

Find out more about improving this business area

See more on People & Culture

Find out more about improving your organization