What is the importance of adopting Daily KAIZEN™ to create a KAIZEN™ Culture

The practice of continuous improvement in organizations is based on adopting a KAIZEN™ Culture by modifying people’s behaviors and beliefs. One of the pillars of this transformation is the implementation of a Daily KAIZEN™ Program.

Daily KAIZEN™ is a program adopted to drive KAIZEN™ behaviors in natural teams at all levels – team leaders and members ” focused on developing people, problem-solving, and sustained improvements. A team and a team leader should be involved from any level and area of an organization. Any team-based department with a process-based workflow that produces any output and aims to improve results, team management, and the environment – such as supply chain, service, development, innovation, or marketing and sales department can participate in the Daily KAIZEN™ program.

To many teams, team leaders are not doing their work correctly as they have no time for managing and supporting them, nor for improvement actions. So, the first step is to develop team leaders’ skills for problem-solving and continuous improvement, as well as for managing the team members and engaging them in continuous improvement activities and daily problem-solving. This will be the starting point for implementing the Daily KAIZEN™ Program.

How is the Daily KAIZEN™ Program organized?

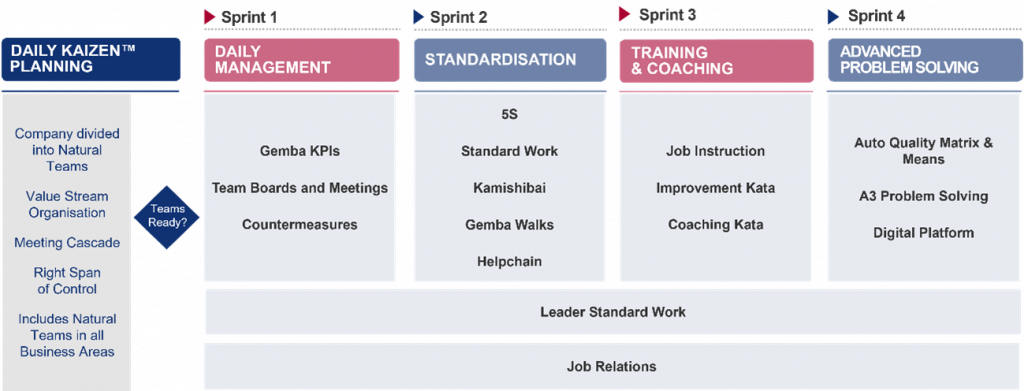

The program implementation plan is based on a roadmap usually organized by sprints and the different capabilities that should be developed during the improvement journey in both the leaders and the team members.

Daily KAIZEN™ Planning

When defining the roadmap, the first step is the Daily KAIZEN™ Planning, completing a readiness assessment to understand if the teams are ready to adopt the daily management practices. This is an analysis of the organization to check whether it is divided into natural teams organized by value streams, what are the meeting cascades, and whether the team leaders have a reasonable span of control.

Daily Management

The first sprint of the roadmap regards Daily Management, where the team leader should use the learned KAIZEN™ Leadership principles and team management skills to involve all employees in frequent, continuous improvement actions. In daily team meetings and by using visual team boards, leaders should identify problems, set targets and control Gemba KPIs, and act immediately with countermeasures.

Standardization

This is followed by the second sprint, “standardization”, to implement better work standards to solve the previously identified problems, using tools such as 5S, Standard Work, Kamishibai, Gemba Walks, and the Help chain.

Training and Coaching

The next sprint is related to Training and Coaching, namely the definition of the job instructions, the Improvement Kata, and the Coaching Kata, which are routines to help the teams and the leaders develop new improvement habits and skills.

Advanced Problem Solving

Lastly, there is Advanced Problem Solving with tools such as Auto Quality Matrix and Means, A3 Problem Solving, and sophisticated digital platforms to manage KPIs.

During the whole process, organizations must check the leaders’ standard work to better use time and resources and understand how the leader can improve the relationships with the team while fostering a culture of openness to change.

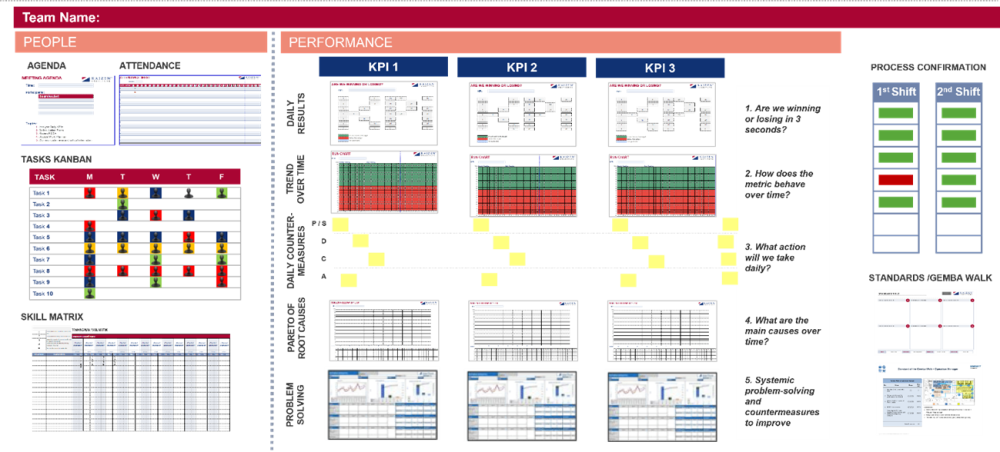

What is the importance of visual boards

The use of performance and problem-solving boards, either virtual or physical, is crucial for the success of the Daily KAIZEN™ Program. It allows the visualization of KPIs to help set up specific countermeasures, increases work organization and planning and enables the possibility of dynamizing the PDCA (plan, do, check, act) model. However, the visual boards have the risk of disaggregating actions or being too big and with excessive information.

The board visuals are appropriate when they allow natural teams to answer the five following questions:

- Are we winning or losing in 3 seconds?

- How does the metric behave over time?

- What action will we take daily?

- What are the leading causes over time?

- How can we eliminate a systemic problem with effective countermeasures to improve?

Other Daily KAIZEN™ skills that should be fostered with visual boards in team meetings are teamwork planning, standard work implementation, use of job instructions to train new people, and improvement of job relations.

A board example:

Why do we need a Daily KAIZEN™ Program?

The goal of implementing a Daily KAIZEN™ Program is to change the organizational culture from traditional to Kaizen™ to steadily increase the portion of the organization that works on improvement. An organization that is managed traditionally is one where unstructured firefighting is common. Namely, recurring problems must be solved, a high amount of muda (non-value-added tasks), and an inability to sustain improvements. The notion of the Daily KAIZEN™ Program arises here to transform this traditional environment into a KAIZEN™ Improvement Culture based on problem-solving with visual management, standardization, continuous improvement, and team members development.

Do you still have questions about Daily KAIZEN™?

What is Daily Management?

Daily management is the creation of practices and routines for systematic monitoring of teams, analyzing deviations and root causes, and identifying opportunities for improvement, to foster a culture of daily continuous improvement where everyone is engaged every day in all areas of the organization.

What is Standardization?

Standardization is a tool of continuous improvement that regards documenting the current best practice for a particular activity, being the easiest and safest to achieve, and maintaining a defined quality level. Once a standard is formed, it may be further improved and help create a new one.

What is Advanced Problem-Solving?

Advanced Problem Solving is the capacity to solve complex problems such as waste reduction, leveraging multifunctional teams and digital tools.

See more on Operations

Find out more about improving this business area

See more on Culture & Organization

Find out more about improving this business area