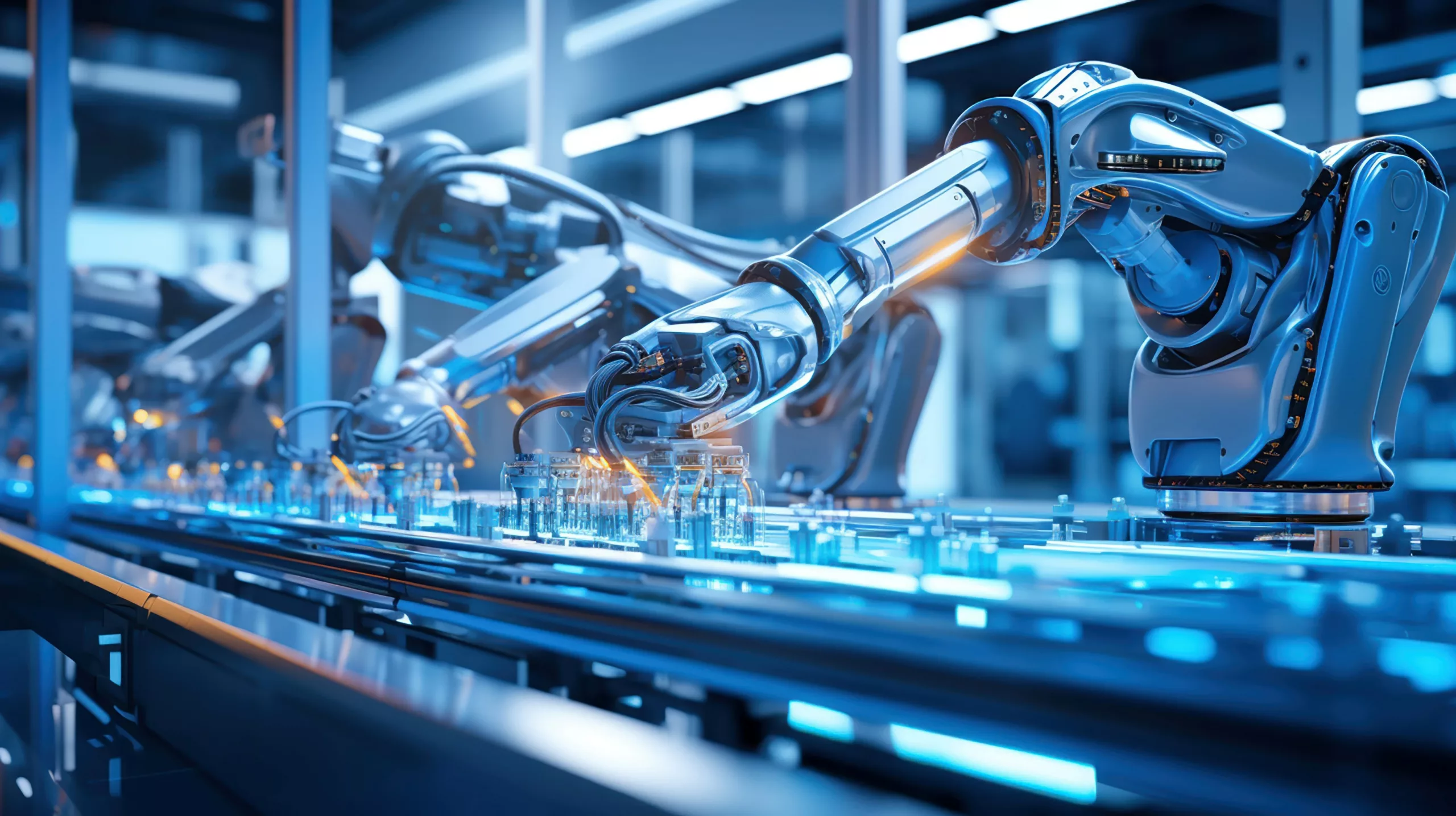

Autonomous & Flexible Operations

Revolutionize manufacturing with autonomous systems and cognitive AI for industry 5.0 transition

There’s a clear need for change in manufacturing due to problems in traditional processes like rigid structures, outdated practices, and challenges such as suboptimal production layouts and excessive reliance on manual labor. On the other hand, over-automation without adaptability, along with issues like unnecessary material handling, operational errors, over-processing, and unreliable resource allocation, hinders productivity.

Moving towards Industry 5.0 is not just about more automation but embracing autonomous systems for better flexibility and efficiency. This involves integrating cognitive AI systems that can analyze large amounts of structured and unstructured data. The goal is to gain insights and make dynamic, informed decisions. This creates a manufacturing era where machines can self-diagnose, adapt, and process complex data in real time for optimized decisions. This higher level of intelligence is crucial for shaping the future of manufacturing.

Traditional Approach

Lean Approach

Traditional Approach

Rigid Operational Structures

Lean Approach

Autonomous Flexibility

Traditional Approach

Over-Automation

Lean Approach

Agile Adaptability

Traditional Approach

Automated Decisions

Lean Approach

Cognitive AI Integration

Traditional Approach

Static Adaptation Mechanisms

Lean Approach

Dynamic Self-Diagnosis in Manufacturing Systems

What can you expect?

Flexibility and Adaptability

Efficiency

Quality and Safety

How to implement Autonomous & Flexible Operations?

Want to know more?

Connect with our experts to explore AI & business analytics solutions tailored to your business needs.

Our Digital Awareness Programs & Seminars

Organized initiatives strategically crafted to raise awareness, disseminate knowledge, and foster understanding among the target audience regarding the realms of digital transformation, business analytics, and artificial intelligence. These initiatives employ various formats, such as presentations, workshops, and interactive sessions to engage participants.

Insights

Want to get more insights?

Explore other digital solutions for different business areas

We leverage business analytics & AI to propel your business into sustainable success in the current digital era.