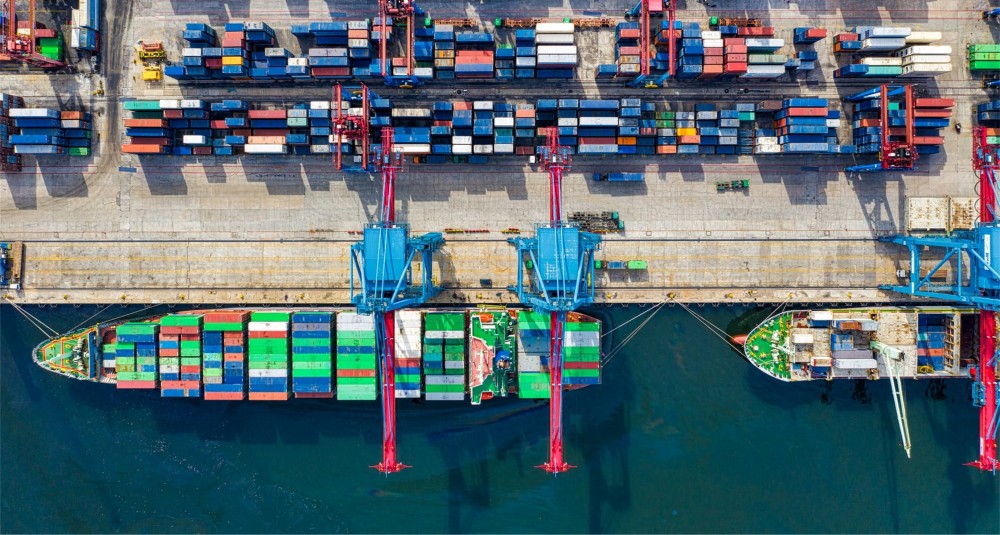

Sourcing and Procurement

Elevate sourcing and procurement to a strategic level with advanced lean supply chain management capabilities

Given the growing importance of supply management, companies are looking to elevate sourcing from an operational function to an integral part of their strategy. Sourcing is the first step in supply chain management and impacts all subsequent activities, making it essential to structure it strategically.

We can help you improve your sourcing system, tailoring a solution specially designed to transform the activities of procurement, purchasing, and supply.

Traditional Approach

Lean Approach

Traditional Approach

Transactional sourcing

Lean Approach

Strategic sourcing

Traditional Approach

Lowest purchase price

Lean Approach

Lowest total cost of ownership

Traditional Approach

Suppliers as providers

Lean Approach

Suppliers as business partners

Our Solutions

We bring a full range of capabilities to help you go beyond transactional sourcing by developing a system that allows you to simultaneously reduce purchasing costs and build internal competencies to sustain results.

- Reshape sourcing.

- Prioritize suppliers according to performance and core capabilities.

- Join forces to achieve savings through economies of scale.

- Establish optimized process parameters and guidelines per category.

- Ascertain target prices through different analytical methods.

- Build better negotiation arguments and leverage competition among suppliers.

- Establish commercial agreements with suitable vendors, ensuring full advantage and compliance.

- Review product features and design to reduce costs.

- Design effective strategies to reduce dependence on powerful suppliers (e.g. backward integration).

- Break away from single supplier deals and approach attractive alternatives.

- Develop strategic partnerships between buyer and supplier to create win-win relationships.

- Conduct a logistics and planning rearrangement to gain productivity, minimize inventories, and speed up the process.

- Implement joint continuous improvement and supplier development programs.

Impact

20 to 25%

Average working capital reduction

25 to 30%

Average spend reduction

20 to 40%

On-time supplies increase

Client results

Learn how to implement it in your organization

Ready to start?

Find out what are the key opportunities in your processes by conducting a diagnosis workshop

Insights

Infographic

A Pull-Flow Transformation Case

Infographic

5 Misconceptions of Supply Chain Transformations

Success Story