Reliability-Centered Maintenance

Implement a reliable and cost-effective approach to maintenance

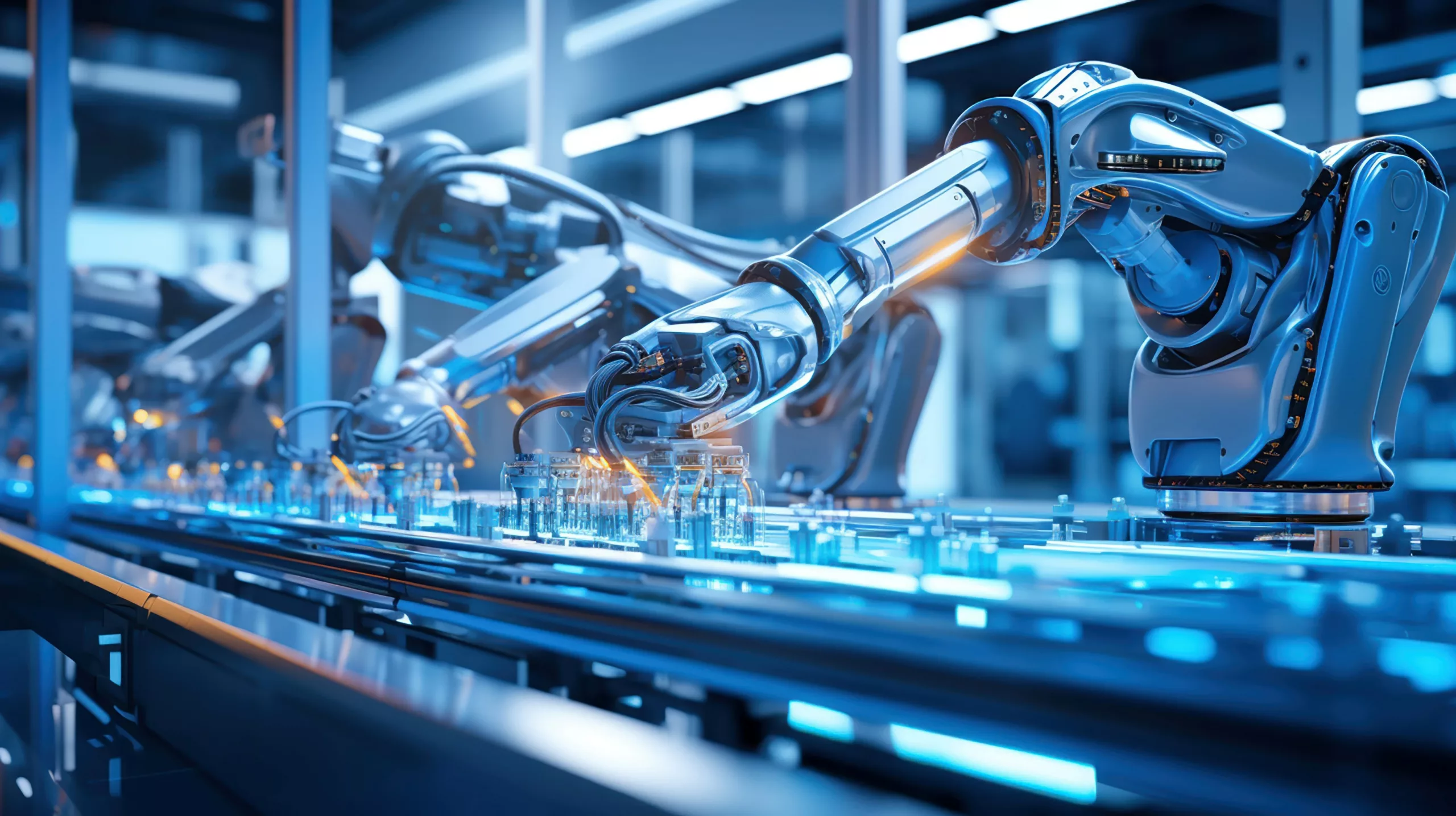

Effective management and maintenance are essential in industries where high quality and equipment availability are crucial. While eliminating downtime is a universal goal, many companies still struggle with predicting the right time for equipment maintenance, leading to unplanned operational halts.

To overcome this, evolving from traditional Total Productive Maintenance (TPM) towards a more data-driven approach is vital. Leveraging predictive analytics and IoT technologies can significantly reduce downtime, offering a more reliable, cost-effective maintenance strategy.

Traditional Approach

Lean Approach

Traditional Approach

Reactive Maintenance

Lean Approach

Precision in Predictive Maintenance

Traditional Approach

Traditional Total Productive Maintenance (TPM)

Lean Approach

Data-Driven Efficiency

Traditional Approach

Unplanned Halts

Lean Approach

Strategic Reliability Centered Maintenance

What can you expect?

Assets Reliability

Cost-effective Maintenance

Resource Efficiency

How to implement Reliability-Centered Maintenance?

Want to know more?

Connect with our experts to explore AI & Business Analytics Solutions tailored to your business needs.

Our Digital Awareness Programs & Seminars

Organized initiatives strategically crafted to raise awareness, disseminate knowledge, and foster understanding among the target audience regarding the realms of digital transformation, business analytics, and artificial intelligence. These initiatives employ various formats such as presentations, workshops, and interactive sessions to engage participants.

Insights

Want to get more insights?

Explore other digital solutions for different business areas

We leverage business analytics & AI to propel your business into sustainable success in the current digital era.