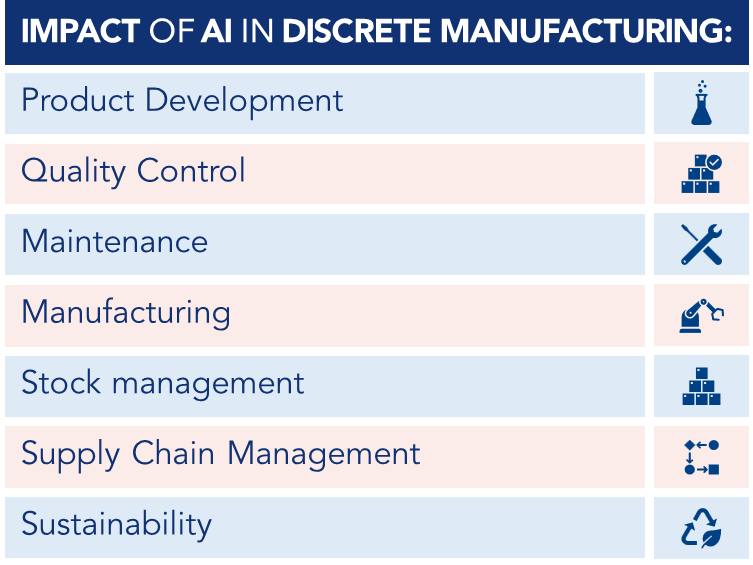

Artificial Intelligence (AI) is redefining the paradigms of discrete manufacturing, promising major transformations in the industrial landscape. AI has impacted product development, production, maintenance, quality management, and many other processes. In this article, we analyze the growing role of AI in reshaping discrete manufacturing, highlighting the opportunities, challenges, and implications of integrating this disruptive technology into modern industry.

AI Applications in Manufacturing

The application of Artificial Intelligence (AI) in the discrete manufacturing industry is transforming how products are designed, produced, inspected, and distributed. AI offers innovative solutions to various industry challenges, increasing process efficiency, quality, and flexibility. The opportunities for use of AI continue to grow and show no signs of slowing down.

Real-time Process Optimization

AI is revolutionizing real-time process optimization by developing AI-driven production systems that can self-adjust based on real-time data analysis. This includes:

- Model Process Control: AI algorithms continuously monitor machine performance and adjust operational parameters to maximize efficiency and minimize wear.

- Failure Prediction: By utilizing machine learning techniques to analyze historical patterns and operational data, AI can predict equipment failures before they occur, reducing downtime.

- Workflow Optimization: Algorithms analyze workflow in real-time and reorganize operations to avoid bottlenecks, thus improving overall productivity.

Autonomous Robotics and Cobots

The introduction of autonomous robots and cobots (collaborative robots) is changing the landscape of the discrete manufacturing industry:

- Flexible Automation: Autonomous robots equipped with AI can perform various tasks requiring little or no readjustment, allowing for more flexible production.

- Human-Machine Collaboration: AI can help cobots designed to work alongside humans to learn and adapt to new tasks, enhancing safety and efficiency on the production line.

- Navigation and Logistics: Autonomous robots use AI to navigate independently within the factory, transporting materials and optimizing internal logistics.

Enhanced Quality Assurance

AI is also developing new processes for ensuring product quality:

- Automated Visual Inspection: Computer vision systems powered by AI perform high-speed visual inspections of products, detecting defects with greater accuracy and speed than humans.

- Predictive Analysis: AI models analyze real-time production data to predict and prevent quality defects.

- Adaptive Quality Control: AI algorithms adjust real-time production processes to ensure product quality meets the desired specifications.

Smart Inventory Management

Inventory management is another area being transformed by AI, resulting in significant cost reductions:

- Demand Forecasting: AI analyzes market trends, sales history, and other relevant data to predict future demand, helping enterprises adjust their production and stock levels.

- Inventory Optimization: AI algorithms determine the ideal stock levels for each product, reducing inventory and minimizing product shortages.

- Real-Time Tracking: AI systems monitor and manage inventory in real-time, providing complete visibility of the supply chain and enabling quick responses to changes in demand or supply issues.

Generative AI for Design and Production

Generative Artificial Intelligence is revolutionizing the design and production sectors in the discrete manufacturing industry. This technology enables the automatic creation of product designs, optimizes material use, and facilitates mass customization. Next, we will explore how generative AI accelerates product development, enables customization, and contributes to increased material efficiency and waste reduction.

Accelerating Product Development

Artificial Intelligence has accelerated the product development process in various ways:

- Rapid Prototype Generation: Generative AI can quickly create multiple product design iterations, allowing engineering and design teams to evaluate and refine concepts in a much shorter time frame.

- Innovative Solutions: AI algorithms can explore design combinations that may not be immediately apparent to humans, resulting in innovative and creative solutions to complex problems.

- Virtual Testing and Simulations: Integrated with simulation tools, generative AI can assess the viability of designs under different operating conditions, speeding up the development cycle by identifying potential failures before physical production.

Customization and Personalization

AI technologies have brought the possibility to customize both the design and production of articles:

- On-Demand Design: Generative AI allows enterprises to offer personalized products to their customers. Using customer data as input, AI systems can generate unique designs that meet specific preferences and requirements.

- Production Flexibility: AI enables production lines to be quickly altered to produce different product variants according to customer specifications. This is accomplished through intelligent automation and advanced robotics.

Material Efficiency and Waste Reduction

Artificial Intelligence, along with recommendation systems paired with simulation and design of experiments models, has introduced various solutions that enhance material efficiency and waste reduction, thereby decreasing environmental impact and costs:

- Material Design: AI can be used to design new materials with specific properties, such as increased strength, lightness, or improved environmental performance. This enables the development of more efficient and sustainable materials.

- Material Usage Optimization: When combined with the aforementioned systems and models, AI can design components and products that use the minimum necessary amount of material without compromising structural integrity. This contributes to sustainability and cost reduction. It can also be applied in product design to make products easier to disassemble at the end of their life, facilitating the recovery and recycling of materials.

- Process Optimization: Through modeling and simulation, AI can optimize production processes to reduce the use of materials and energy. This decreases production costs and minimizes the environmental impact associated with producing new products.

Enhancing Operational Efficiency with AI Solutions

As mentioned earlier, the implementation of various AI-based solutions significantly and positively impacts operational efficiency in discrete manufacturing industries. These technologies also offer solutions to optimize energy consumption and enhance the visibility and forecasting of the supply chain, two vital components for operational success and environmental sustainability.

Energy Consumption Optimization

AI solutions enable the optimization of energy consumption in discrete manufacturing processes:

- Energy Efficiency in Production: Generative AI can significantly reduce energy consumption by optimizing production processes. This includes improving thermal processes and reducing machine downtime.

- Intelligent Management of HVAC Systems: Heating, Ventilation, and Air Conditioning (HVAC) systems can be optimized with AI to automatically adjust settings based on environmental conditions, occupancy, and other variables, reducing energy consumption.

- Smart Grids: Generative AI can optimize energy distribution in the electrical grid, predict energy consumption, and efficiently integrate renewable energy sources, contributing to more sustainable energy resource management.

Supply Chain Visibility and Forecasting

AI technologies provide a global view of the supply chain and enable highly accurate demand forecasting:

- Demand Forecasting: AI analyzes market trends, historical sales data, and other external factors to predict future demand accurately. This helps enterprises adjust their production and inventory, avoiding excesses and shortages.

- Real-Time Tracking and Monitoring: AI solutions offer real-time visibility into the movement of materials and products throughout the supply chain, allowing quick responses to disruptions or delays.

- Transport Route Optimization: Using AI, enterprises can determine the most efficient routes for product delivery, considering factors such as traffic, weather conditions, and fuel costs. This not only improves logistical efficiency but also contributes to reducing carbon emissions.

AI’s Role in Predictive Maintenance and Process Control

Artificial Intelligence is transforming predictive maintenance and process control in discrete manufacturing industries. These technologies increase operational efficiency and ensure process consistency, which is crucial for product compliance.

Ensuring Process Consistency for Product Compliance

AI applied to predictive maintenance and process control allows enterprises to anticipate failures before they occur and ensure process consistency, thus also ensuring product quality:

- Predictive Maintenance: Sensors collect real-time operational data from equipment, allowing continuous monitoring of their condition. AI analyzes this data to identify abnormal trends or patterns that indicate potential failure, enabling enterprises to schedule maintenance proactively and avoid unexpected and costly downtime.

- Parameter Optimization: AI algorithms dynamically adjust process parameters in response to variations in raw materials, environmental conditions, or other operational factors, keeping production within specifications.

- Anomaly Detection: AI can also detect deviations in real-time, alerting operators to inconsistencies that may affect product quality and allowing for immediate corrections.

Navigating the Challenges of AI Integration in Manufacturing

Integrating Artificial Intelligence (AI) in the discrete manufacturing industry presents enormous potential, but it also brings a series of challenges. Among these are concerns about integrating AI with existing systems and the need to develop skills and adapt the workforce. Addressing these challenges is crucial for maximizing the benefits of AI and ensuring a smooth and responsible transition to future production paradigms.

Integration with Existing Systems

Many factories operate with a mix of new and old technologies, including equipment and software that may not have been designed for interoperability. Effectively integrating AI under these conditions may require customized solutions or significant upgrades.

Effective integration of AI with existing systems requires an approach that considers technical aspects as well as organizational and strategic implications. Properly managing this challenge can unlock significant operational and competitive benefits for the discrete manufacturing industry.

Skill Development and Workforce Adaptation

Successful integration of AI also depends on an enterprises’ ability to develop their employees’ skills. This involves training people in new technologies and promoting a culture of learning and continuous improvement that values innovation. As AI takes on operational tasks, new roles focused on advanced human skills will emerge, necessitating a reorientation of the workforce to seize these new opportunities.

The Future is Automated: AI’s Evolving Role in Smart Manufacturing

As we move towards an increasingly digitalized era, the role of Artificial Intelligence in intelligent manufacturing is evolving, paving the way for innovations that promise to revolutionize the industry. The integration of emerging technologies into the new paradigms of industry, along with a growing emphasis on sustainability, highlights the increasing importance of AI in optimizing production, energy efficiency, and waste reduction.

Emerging Technologies and Industry 5.0

Industry 4.0 introduced the concept of smart factories and industrial automation, where various technologies such as artificial intelligence, the Internet of Things (IoT), robotics, and cloud computing are integrated to create an automated and interconnected production ecosystem.

As we enter Industry 5.0, the interaction between humans and machines is redefined. Collaboration between artificial intelligence and human intelligence is encouraged to achieve more personalized, efficient, and flexible production. AI automates repetitive tasks and empowers workers, enhancing creativity and decision-making.

The Role of AI in Sustainable Manufacturing Practices

Artificial Intelligence is helping discrete manufacturing industries become not only more efficient but also more sustainable.

This transformation is made possible by AI’s ability to optimize energy consumption, improve resource utilization, contribute to developing more sustainable products, and many other improvements with environmental impact.

This approach optimizes production processes and is a step towards adopting a circular economy in industries.

Still have some questions about AI in Manufacturing?

What are the implications of AI for the global supply chain?

Integrating Artificial Intelligence (AI) into the global supply chain has varied implications. First, AI can significantly increase efficiency by automating decision-making processes, from demand forecasting to delivery route optimization. This results in reduced operational costs and faster delivery times. Additionally, AI provides greater supply chain resilience by improving the response to unexpected disruptions, such as those caused by natural disasters or sudden fluctuations in demand. By offering real-time visibility and predictive insights, AI helps enterprises adapt quickly, minimizing negative impacts.

What role does AI play in customizing manufacturing processes for small-scale producers versus large-scale manufacturers?

Both small-scale and large-scale manufacturers can benefit from AI, but the scale of implementation and strategic focus may vary. Small producers may focus more on customization, flexibility, and operational efficiency, while large-scale manufacturers can leverage AI for supply chain optimization, mass customization, and research and development, taking advantage of their broader resources and complex operational needs. AI technologies’ adaptability allows them to be scaled according to the needs and capabilities of the enterprise, making them a valuable tool in all aspects.

What are the ethical considerations when implementing AI?

When implementing AI, various ethical considerations must be addressed. Transparency in automated decision-making is crucial, especially in applications that directly affect people, such as job candidate selection or price personalization. Additionally, bias and fairness issues arise when AI systems are trained on historically biased data sets, potentially perpetuating, or even amplifying these injustices. Data privacy is also a paramount concern, and stringent data protection measures must be implemented to prevent abuses. Finally, the implementation of AI raises questions about the impact on employment and society, challenging us to find ways to ensure that the benefits of AI are distributed fairly and that opportunities are created for those potentially displaced by automation.

See more on Digital & AI

Find out more about improving your organization

See more on Discrete Manufacturing

Find out more about transformation in this sector