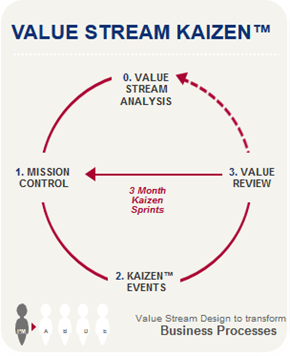

A Value Stream KAIZEN™ Program is a program composed of a four-step roadmap with the goal of improving value streams through KAIZEN™ Events.

The program starts with a Value Stream Analysis. After this, a Mission Control Room is established, followed by the KAIZEN™ Events execution and a quarterly Value Review. The Value Stream KAIZEN™ program begins with setting a breakthrough vision and KAIZEN™ goals, while developing an end-to-end value stream analysis.

Why implement a Value Stream KAIZEN™ Program?

Implementing a Value Stream KAIZEN™ Program makes it possible to upgrade from an outdated organizational culture to a KAIZEN™ Culture, with resource to world-class benchmarks. Known as an improvement process to design and implement breakthrough initiatives, the Value Stream KAIZEN™ Program transforms organizations through projects and KAIZEN™ Events using state of art best practices.

What are the steps to implement a Value Stream KAIZEN™ Program?

Value Stream Analysis

The first step is to undergo a value stream analysis. The Value Stream KAIZEN™ Program requires mastering the end-to-end value stream analysis approach with the necessary benchmark tools for lean implementation. The Value Stream Analysis includes current state analysis, training, and the definition of the future vision. Lastly, a roadmap for the implementation of Gemba KAIZEN™ Workshops is designed. The vision and opportunities, alongside the ROI and results, are represented in a business case report.

Mission Control

The second step, implementing the Mission Control using visual project management tools, allows the follow-up of the results achieved with the Gemba KAIZEN™ Workshops. This step includes a Mission Control design workshop, a Mission Control project management practice, and the definition of the Lean Project Management principles with A3 Thinking.

KAIZEN™ Events

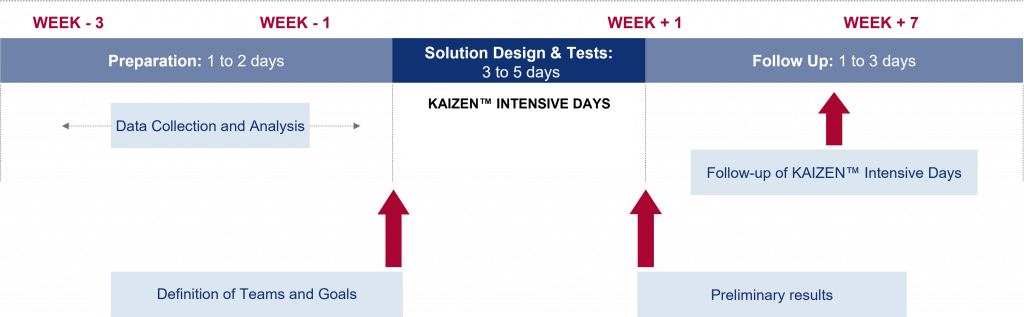

The third step is to perform KAIZEN™ Events. The implementation is carried out in three months KAIZEN™ Sprints. The KAIZEN™ Events allow to follow the implementation priorities with the support of the 9-Step A3 process. Lastly, an SDCA Confirmation Workshop is carried out to validate the effectiveness of the new standards in the Value Stream.

Value Review

The final and last step is a Value Review Workshop to assess if the KAIZEN™ Events produced the expected results. During this workshop, a Cycle Performance Review is carried out. This is done by establishing Value Trees, reviewing the next cycle’s targets, and planning the implementation of the next sprint. Alongside, a KAIZEN™ Prioritization Process helps to accurately design the Value Stream vision for the company.

The KAIZEN™ Blitz Workshop

The fastest way to implement a Value Stream KAIZEN™ Program while learning and improving is through an intensive and goal-driven improvement workshop – The KAIZEN™ Blitz Workshop. The workshop is held at the Gemba, the place in an organization where work is being performed. This is conducted by the workshop team, using a similar approach to the Toyota Blitz approach – a fast implementation – and a standard methodology, the A3 Thinking. Another characteristic of this KAIZEN™ Workshop is the use of quick countermeasures to achieve results with little investment and financial benefits. It is the best way to train management and internal consultants on how to do KAIZEN™.

Which organizations can benefit from a Value Stream KAIZEN™ Program?

Every organization can execute an in-depth Value Stream Analysis to develop a future breakthrough vision. In preparation, companies should plan for key value streams and design the vision based on paradigm shifts so that the implemented Mission Control and KAIZEN™ Events are set accordingly to the company’s goals.

By performing Value Reviews and implementing an agile approach with KAIZEN™ Events, it is possible to generate the expected results of the Value Stream KAIZEN™ Program. It is also essential to identify, within the Value Stream Analysis, how to eliminate waste – Muda. The Value Stream KAIZEN™ Program offers a benchmark toolbox and guidelines to eliminate waste and to help companies achieve their goals in a standardized way.

Systems, improvement methods and tools

The Value Stream KAIZEN™ Program applies not only to Supply Chain Excellence but also to service centers and departments, such as human resources and finances. The toolbox to optimize E2E supply chains and processes that are demanding-driven, lean, agile, and resilient is composed of: demand-driven planning, sourcing excellence, Lean Production System, Lean Distribution System, and fulfillment excellence.

These tools and processes aim to improve the transactional process, optimize office planning, create flow and efficiency so as to optimize the lean service centers. Furthermore, the program applies E2E excellence to maximize business growth through agile product development, innovation, design, ideation, and design thinking product management excellence, as well as ESG Sustainability and marketing and sales excellence.

Do you still have questions about Value Stream KAIZEN™?

What is a Value Stream?

Rother and Shooko (1999) define Value Stream as the set of all activities – both value-adding and non-value-adding – currently required to produce a product, service, or combination thereof. Thus, these represent a sequence of activities needed to design, produce, and deliver a given good or service to the customer.

What is Value Stream Mapping?

Value Stream Mapping, or VSM, is a powerful visual tool used in Value Stream Analysis (VSA) to depict and improve the materials and information flow required to bring a product or service from conception to delivery. It breaks down the process into three key components: material flow, information flow, and process data, offering a comprehensive view of the operations’ current state and highlighting waste.

The VSM process is thorough; understanding the existing challenges is crucial before jumping to solutions. By examining the current VSM, teams can pinpoint areas to enhance efficiency, reduce waste, and mitigate delays. Common issues such as excess inventory, defects, and overproduction are addressed, with additional consideration for safety, quality, and environmental impact.

What is E2E?

E2E, or End-to-End solutions, are the processes where a system or service is completely carried out without assistance from a third party. With E2E, the company can strive to deliver a fully functional system, service, or project from start to finish.

What is A3 Thinking?

A3 Thinking lies at the core of lean management as a practice of describing and analyzing a problem, creating an action plan, and the corresponding corrective actions on a single sheet of large (A3) paper, often with the use of graphics.

Discover Value Stream Analysis Training

Find out more about improving your organization

See more on Culture Transformation

Find out more about improving your organization