Defining Kaizen: A Continuous Improvement Philosophy

The Kaizen concept, deeply intertwined with Japanese work ethic and management culture, has become a cornerstone of global operational strategy since it gained popularity through the book ‘Kaizen: The Key to Japan’s Competitive Success’ in 1986. Kaizen, which means “continuous improvement” in Japanese, is based on the belief that significant outcomes can be achieved through small incremental changes. It is a long-term practice meticulously integrated into a company’s culture.

Toyota is an example of the impact of the Kaizen methodology on a company’s success. Toyota surpassed General Motors, becoming the world’s largest automobile manufacturer. The continuous improvement philosophy has been a key factor in Toyota’s global success, demonstrating that small, consistent improvements can result in superior quality and operational efficiency.

Kaizen stands out for its approach to gradual and continuous changes, contrasting with Western methods that often favor larger innovations and radical technological changes. This approach is a customer- and workplace-centered strategy (Gemba) and a philosophy all employees embrace, encouraging daily reflection on optimizing work practices and efficiency. This method enables progressive evolution, aligning with a low-risk quality and change management approach, making it particularly suitable for environments where continuity and stability are crucial.

The term “Kaizen” is acknowledged in the Oxford Dictionary as an English word, indicating its integration and perceived added value beyond Japanese borders. Its global adoption demonstrates how effective and universally applicable these Japanese management principles are, further evidenced by the international dimension of the Kaizen Institute.

Next, we explore the history of Kaizen after World War II, to better understand how this philosophy evolved and was integrated into contemporary management practices.

Tracing the Roots of Kaizen: Its Emergence and Evolution Post-World War II

Kaizen traces back to post-war Japan. Economically and industrially devastated, the country faced the pressing need to rebuild and restore its industries. Japan sought ways to reinvent its production and management processes in this renewal era. Inspired in part by the quality and efficiency practices observed in the United States, particularly through the influence of experts like W. Edwards Deming, Kaizen was adapted to meet the Japanese specificities and work ethic.

Kaizen became a central element in Japan’s recovery strategy, enabling constant process improvement and continuous employee development. This approach promoted a continuous improvement culture that significantly increased Japanese companies’ quality and competitiveness. This continuous improvement spirit allowed Japan to position itself as a global economic power rapidly and laid the foundation for what would become the Japanese Economic Miracle.

This approach of gradual improvement, as opposed to drastic changes, proved that the sum of small improvements could lead to significant developments. In this sense, Kaizen established a legacy from the past that continues to inspire the present and shape the future of organizations worldwide.

By understanding how Kaizen emerged from the ashes of war to become a global philosophy, we will gain a better perception of its gradual approach to change, which will be analyzed in the following part.

Kaizen as a Concept: Step-by-Step Change

As a practice, the Kaizen methodology is defined by small changes applied consistently and systematically. It is a progressive yet persistent evolution, where each small improvement is part of successive adjustments, leading to significant long-term transformation. This philosophy encourages organization members to closely observe their work methods daily, and seek improvement opportunities, even if they are small.

It is an inclusive approach that values each contribution, recognizing that even the smallest suggestion can provide a lasting competitive edge.

From this viewpoint, Kaizen is not limited to production or operational efficiency; it encompasses all aspects of the company, including management, services, and support. Any process can be improved, and every employee can be a potential improvement agent. By adopting this approach, Kaizen establishes a culture where excellence is the norm, sought in the smallest detail and at all organizational levels.

This gradual and inclusive approach to improvement will continue to be the foundation upon which improvement – the fundamental principles that support and materialize Kaizen in the current business environment – is built.

Kaizen Foundations: The Improvement Cornerstones

Kaizen’s foundations rest on key principles guiding organizations toward continuous and systematic improvement. Among these principles is the need to add value for the customer and optimize workflow efficiency. The Kaizen approach also emphasizes the importance of being present in the field (Gemba), empowering employees, and adopting a scientific and transparent approach in all processes.

Kaizen’s continuous improvement tools, such as the 5S (Seiri – Sort, Seiton – Set in order, Seiso – Shine, Seiketsu – Standardize, Shitsuke – Sustain), visual management, standardization, and the PDCA cycle (Plan, Do, Check, Act), are essential to supporting these principles and overcoming the challenges associated with change.

Resistance to change is often the biggest challenge companies face when implementing Kaizen. However, overcoming this resistance is crucial for observing Kaizen principles and eliminating the “7 Mudas”—waste that hinders efficiency such as overproduction, waiting time, unnecessary movements and transportation, overprocessing, errors, and defects.

These principles lay the groundwork for modern management inspired by Kaizen, which will be explored next, revealing how a continuous improvement mindset can transform leadership and organizational culture.

Kaizen Management in Modern Leadership

Embracing Kaizen in modern leadership models requires reevaluating traditional management practices, placing continuous improvement at the heart of leadership strategy. This implies an openness to learning and constant evolution, where leaders must lead by example and encourage and facilitate every employee’s active involvement in the improvement process. A Kaizen leader breaks down seniority barriers to foster transparent communication, acknowledging that ideas and knowledge can come from any level of the organization.

In this context, leadership is characterized by a participative approach, where employee feedback and ideas are valued. This requires transparency in decision-making and sharing knowledge and liabilities. Furthermore, leaders must be change facilitators, identifying and addressing resistance to change, often through education and Kaizen training.

This leadership model generates an organizational culture where value is created by adhering to standards and continuously committing to improving them. It highlights the essential role of leadership in framing and implementing Kaizen principles in the company.

By integrating Kaizen principles into leadership, companies can naturally connect with Lean Management methodologies, forming a powerful pair to achieve operational excellence.

Kaizen and Lean Management: Partners in Pursuing Excellence

The Kaizen method, centered on continuous improvement and incremental innovation, harmoniously associates with Lean Management principles to pursue operational excellence. Lean Management, focusing on maximizing value for the customer and eliminating waste, finds in Kaizen a complementary partner focused on progressive and constant improvements at all organizational levels.

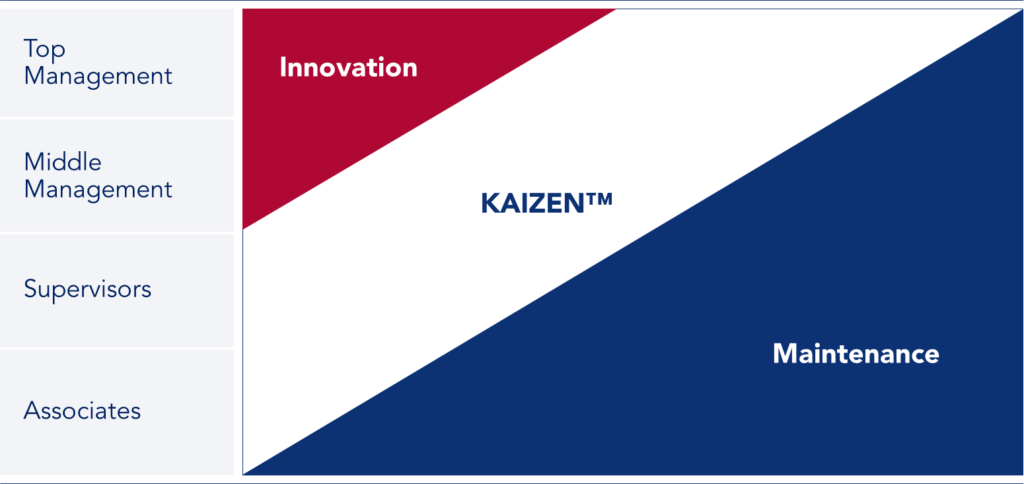

In the context of Kaizen, management is divided into two essential functions: sustaining and improving. Sustaining refers to actions aimed at maintaining current standards through training and discipline, ensuring that standardized operating procedures are rigorously followed. Improvement, on the other hand, focuses on refining these standards, where innovation is not seen as a costly alteration, but as a series of logical and progressive improvements resulting from an efficient communication. These two sides reflect the Japanese work function perception, where every level, from operators to top management, is involved in continuous improvement and maintenance (activities aimed at maintaining current technological, management, and operational standards).

The integration of Kaizen into Lean Management can be seen by adopting these principles of continuous improvement as part of a broader Lean strategy, which brings together the vision of operational excellence and an improvement culture across the company.

How Kaizen Strengthens Lean Principles

Kaizen, with its commitment to continuous improvement and the involvement of all employees, significantly strengthens Lean Management principles. This philosophy introduces a dynamic of constant improvement into Lean, essential for sustaining its benefits. Through the small innovations encouraged by Kaizen, Lean processes become more efficient and more reactive to changes and improvement opportunities.

Kaizen and Lean work together to eliminate waste and optimize value flows. Kaizen deepens the application of Lean principles by scrutinizing each step for efficiency gains, even minimal ones. This creates an environment where Lean process standardization is constantly reassessed and improved instead of simply maintained.

Embedding Kaizen in Lean practices creates a culture where improvement is not a project with a beginning and end but a core part of daily work. This culture is precisely what allows Lean principles to become deeply rooted in organizations.

The next step in consolidating this continuous improvement culture lies in using PDCA/SDCA cycles effectively as refinement tools within the Kaizen methodology.

PDCA/SDCA Cycles: The Kaizen Improvement Tool

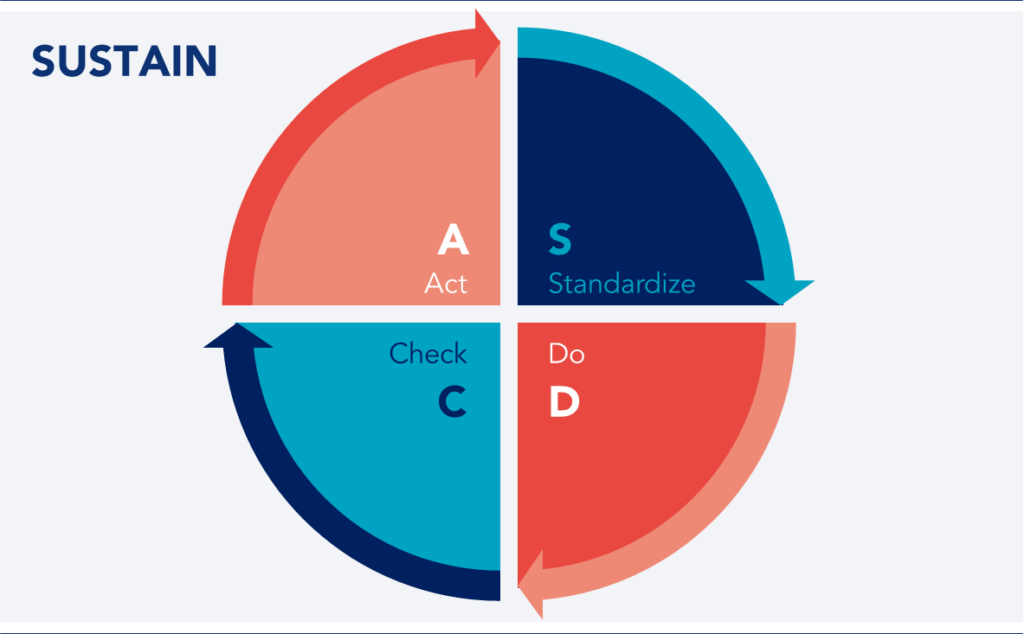

The PDCA (Plan, Do, Check, Act) and SDCA (Standardize, Do, Check, Act) cycles are at the heart of the Kaizen approach, serving as engines for continuous process improvement and maintaining standards. The PDCA, often referred to as the Deming Wheel, is an iterative quality management model that promotes continuous improvement through a logical sequence of steps: planning the improvement, implementing it, checking the results, and acting accordingly to prolong the change.

The cycle begins with planning, where clear objectives are defined, and action plans are developed. The execution phase rolls out these plans. This is followed by verification, where the results are assessed to ensure they meet expectations and are on track to achieve good outcomes. Finally, the action stage allows for standardizing achievements and integrating improvements as a regular practice.

The SDCA cycle emphasizes the importance of standardization as a precursor to the PDCA improvement cycle. Here, the perspective is that before seeking to improve a process, it is essential to ensure that current procedures are stable and standardized. The organization can effectively move to continuous improvement through the PDCA cycle only after establishing these standards.

Thus, the SDCA cycle normalizes and stabilizes current processes, while the PDCA cycle improves them. SDCA refers to sustaining standards, and PDCA to improvement; these elements constitute the two main management responsibilities.

These cycles are not just tools for improvement but also show Kaizen’s commitment to a constant operational excellence culture where innovation is continuous and the status quo is always questioned.

Following the Deming wheel, companies adopt a systematic approach to continuous improvement, which will be analyzed below in the discussion of how it guides and supports continuous improvement in organizations.

The Deming Wheel for Continuous Progress

The Deming Wheel, also known as the PDCA cycle, is a fundamental tool in the Kaizen methodology, facilitating continuous progress through repetitive and structured improvement cycles. Starting with planning (Plan), organizations define objectives and prepare action plans. Implementation (Do) involves executing these plans and a verification (Check) to examine the results. The final phase – acting (Act) – involves adjusting and standardizing new best practices to consolidate progress. This dynamic cycle drives a culture of constant improvement, where learning and adaptation are permanent.

By focusing on this cyclical process, companies ensure that improvement is sustainable and adapts over time to conditions or objectives changes. In sum, this approach allows for achieving short-term goals and laying the foundation for long-term improvements.

Applying the Deming Wheel enables a continuous measurement and process comparison against their outcomes. Given its critical role in evaluating the success of the Kaizen method within any organization, this essential step will be scrutinized more closely in the following section.

Process vs. Outcome: Measuring Kaizen Success

The Kaizen method focuses on process rather than result, a perspective that differs from the traditionally results-oriented Western approach. This thinking states that outcomes purely reflect the quality of the underlying processes. In this view, a failure in outcomes is interpreted as a faulty process needing identification and correction.

Implementing Kaizen strategies, such as the PDCA and SDCA cycles, as well as practices like Total Quality Management (TQM), Just-in-Time (JIT), and Total Productive Maintenance (TPM), heavily depends on this process orientation. The failure of Kaizen strategies is frequently attributed to not focusing on processes as much as results.

When following a Kaizen methodology, measuring success means assessing the effectiveness of processes and their continuous improvement. Success is defined by the ability to consistently maintain and improve standards, implying management’s direct responsibility to lead these improvements.

By recognizing the importance of process quality, a solid foundation is established for implementing Kaizen principles, which are essential for achieving advanced quality in all aspects of the company.

Quality Above All: Implementing Kaizen Principles

In implementing Kaizen principles, quality is paramount and must always be the top priority. The QCD (Quality, Cost, Delivery) places quality at the top of the scale, supporting the idea that without quality, neither cost advantage nor delivery speed can secure a sustainable competitive edge. A quality orientation requires a firm commitment from management to acknowledge that compromising on quality to meet deadlines or reduce costs can jeopardize the company’s viability in the long term.

Adopting an approach where quality comes first means that top management must resist the temptation to take shortcuts. This implies maintaining high standards in all processes and ensuring that each improvement introduced adds value and does not negatively impact the quality of the product or service offered to the customer. In practice, this means integrating quality into every step of continuous improvement, an approach that meets and exceeds expectations.

Kaizen principles can influence not only internal processes, but also customer perception and satisfaction by placing quality at the center of every decision.

Quality First in the Improvement Strategy

The Kaizen improvement strategy places quality at the top of its priorities, stating that a quality product or service is the foundation of sustainable market competitiveness. In this approach, every process improvement step is examined to ensure it contributes to elevating quality. This requires constant monitoring and a commitment from management not to sacrifice quality for short-term gains, such as cost reduction or faster delivery times.

Consequently, quality is perceived not as a cost but as a strategic investment, where initial expenses in quality improvements turn into long-term benefits, such as customer loyalty and reduced non-compliance costs.

The commitment to quality, driven by Kaizen principles, is an approach that requires data-based analysis, as measures map out the path for continuous improvement.

Speaking with Data: The Importance of Measurement in Kaizen Methodology

Speaking with data means making decisions based on quantifiable and verifiable information rather than assumptions or intuition.

By measuring, we provide a common language for all stakeholders, facilitating performance communication and understanding at all organization levels. Speaking with data also allows setting clear objectives and celebrating successes when key performance indicators show improvements. Ultimately, by working with data and measuring it frequently, we can help transform small wins into major successes, embedding a continuous improvement culture into the company’s DNA.

In conclusion, the Kaizen methodology, emphasizing quality, continuous improvement, and using data to guide decisions, offers an effective framework for operational excellence.

Still Have Questions Regarding Integrating Kaizen with Lean Management?

What is the Deming Wheel?

The Deming Wheel, also known as the PDCA cycle, is an interactive management and continuous improvement model that includes four phases: Plan, Do, Check, and Act. This cycle is used to establish a quality process in organizations and promote continuous improvement in products, services, and processes.

What are the Kaizen Essentials?

The Kaizen foundations are the basic principles supporting this continuous improvement philosophy. They include the continuous improvement of all processes, the involvement of all employees, customer-focused improvement, small changes over large ones, and the standardization of successful processes. These principles aim to create a culture of efficiency and operational excellence.

See more on Lean

Find out more about improving this business area

See more on People & Culture

Find out more about improving your organization