The expectations around the value supply chains deliver are growing due to the ongoing volatility and uncertainty of global markets. The rising route and materials costs and the acceleration of digitalization are some of the events challenging the industry to innovate with competitive ideas.

In today’s demanding environment, supply chain optimization is part of a new paradigm for achieving breakthrough results and competitive advantage in terms of both customer service and profitability, as it becomes crucial for organizations to be aware of the key strategies that can be applied to improve supply chains, to become more resilient, and stronger against disruption.

What is Supply Chain Optimization?

The key drivers for supply chain optimization are risk, instability, disruption, increasing customer expectations, rapidly changing markets, inflation, and volatility of demand. To respond to these new realities and opportunities, organizations must rethink strategies and adjust processes, ensuring that operations work according to the principles of end-to-end, demand-driven, agile, and lean. These principles will bring the capacity to recover quickly from difficulties and be prepared to mitigate risks and are crucial to providing the best customer experience and enhancing the overall success of the business.

So, an optimal supply chain is one that delivers exactly what the customer wants, where it is wanted and when it is wanted, without fail, much faster than the competition and with minimal customer service loss and cost impact.

5 Common Weak Spots in a Company’s Supply Chain

In today’s business context, there are plenty of opportunities to improve the state of a supply chain:

- Long Lead Times create inflexibility in the supply chain, reducing agility and responsiveness to respond to market demand.

- Structural issues such as long Planning Frozen Periods and large Minimum Order Quantities (MOQ) are flow breakers driving Lead Times up.

- Inefficiencies and non-value-added activities drive variability in the Lead Time and low on-time delivery.

- The result of this inflexibility and variability is high inventory which creates excessive stock costs and a lot of vulnerability to demand variability.

- Lack of standards in the definition of the supply chain network.

To face these difficulties with quickness and effectiveness, organizations need to continuously improve towards optimizing supply chain processes.

Steps and Strategies to Increase the Efficiency of your Supply Chain

Supply chain leaders must look for organizational structures and business models that solve these challenges, maximize efficiency, and deliver extraordinary results, regardless of the environment.

Some supply chain improvement initiatives are the following:

- Build the flow of information and products throughout the value stream by minimizing non-value-added activities.

- Design differentiated and sustainable supply chain segments to serve different demand & market requirements.

- Build agility and flexibility in the supply chain to respond to changing market dynamics and new business models.

- Enable the right sizing of the fixed asset and improve working capital by reducing inventory.

However, before kick-starting the improvement process, it is necessary for organizations to master the 5 key analyses for supply chain optimization.

5 Key Analyses for Supply Chain Optimization

1. Demand analysis (ABC/XYZ analysis)

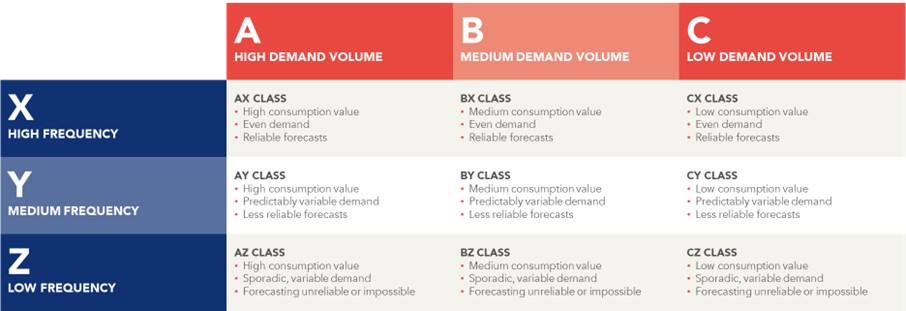

This analysis refers to the classification of all ordered SKUs according to volume and frequency of demand, being the basis for the definition of differentiated SKU Stock Strategies. The ABC Analysis ranks and groups SKUs by their sales revenue, while the XYZ looks at the frequency and variability of demand.

2. Inventory analysis (current stock vs. optimized stock)

This key analysis is similar to the previous one but applied to the SKU inventory. It is a classification of all inventory SKUs based on the amount of inventory and frequency of picking/dispatch, along with a calculation of the optimal inventory. Additionally, the ‘dead stock’ – stock that has no movement – can be identified.

3. Production analysis (every product, every interval (EPE) analysis)

It is important to evaluate the production Lead-Time, however, it usually happens in the middle of a replenishment cycle and is difficult to measure. The EPE Analysis is an analysis of production replenishment lead-time and production agility (flexibility) for small batch production.

In a sense, it expands the previous inventory analysis, meaning that we must understand what is happening in the replenishment lead-time, namely, how capable and flexible the production lead-time component is.

To do that, the EPE analysis of the main production equipment must be performed. In most cases, the EPE analysis can result in a Lead Time reduction of more than 50%, and the inventory can be decreased accordingly.

4. Supplier analysis (Kraljic Matrix)

The Kraljic Matrix is a way of grouping supplies into four strategic spend categories: strategic, leverage, routine, and bottleneck. To do so, it is necessary to classify spending (the Y-axis) and supply risk (the X-axis), which will, in the end, reflect the business impact and risk of the investment in supplies, as well as provide relevant information about the specific suppliers.

5. Supply chain lead-time analysis

The final key analysis follows all the previous ones as it integrates the whole supply chain, and is, therefore, the main target for supply chain improvement. It is a calculation of the total inventory in a supply chain, and an estimate of the total supply chain lead time from the initial supplier until the last customer, based on the classic value stream mapping approach. The focus on lead-time reduction may lead to doubling productivity and reducing costs by 30%.

Do You Still Have Questions about Supply Chain Optimization?

What is Lead-Time?

Lead Time is the amount of time that passes from the beginning of a process until its conclusion. Specifically, in supply chains, lead time represents the time it takes from the initial supplier until the end consumer.

Some factors that impact Lead-Time include lack of raw materials, breakdown of transportation, or labor shortages. There are many strategies that companies can adopt to improve lead time, for instance, the implementation of automated stock replenishment to consequently boost the entire supply chain performance.

What is Stock Replenishment?

In the supply chain, stock replenishment is an operation that consists in ensuring the right amount of stock, at the right time in the right place, to fulfill customer demand and minimize inventory costs.

What is an Agile Supply Chain?

An agile supply chain is focused on responding to risk and disruption with flexibility and quickness, relying on real-time demand data for decision-making. Agile principles should be adopted on a daily basis in supply chain management to maximize cost and performance efficiency despite adverse circumstances.

See more on Logistics

Find out more about transformation in this sector

See more on Warehousing & Transporting

Find out more about improving this business area