All organizations should have a team management model that allows them to create a culture of improvement and drive sustained growth. However, many companies still face the challenge of dealing with reactive management, in which they are constantly “putting out fires” and dealing with urgent problems, unable to focus on improvement activities.

The goal is to move from a traditional management model where “firefighting” is the daily routine to a culture of continuous improvement. To do this, it is necessary to transition from a scenario where problems are recurring, where the amount of non-value-added tasks is large, and where there is an inability to sustain improvements, to a scenario where there is effective problem-solving, where processes are standardized, and where teams are focused on improving and growing.

Organizations need a structured program for implementing effective team management. This article will explore the importance of these programs and deployment models.

What is Structured Team Management?

Team management should be based on a development program for the leaders of natural teams to make them autonomous in the application of continuous improvement within their scope of action. This empowerment allows teams to maintain and improve their processes daily. Through structured implementation, these programs promote the basic stability of the organization’s internal processes and consolidate the improvements achieved in the project scope. A team management program should follow a bottom-up approach and aims to develop the skills of leaders, making them capable of teaching, guiding, and motivating their teams to improve continuously .

Benefits of Structured Team Management

A good team management program has several advantages for organizations that implement them. Trained leadership focused on the organization’s priorities facilitates the implementation of defined strategic initiatives. On the other hand, the maturity acquired by teams in implementing improvements, which can be seen in new habits of analyzing, questioning, and solving problems, is fundamental for sustaining results.

Here are some of the main benefits that a good team management model can bring to organizations.

Organization Alignment

Structured team management promotes alignment throughout the organization. When teams are managed in a coordinated and effective way, it positively impacts the entire company, enabling objective alignment, cooperation between areas, and results maximization.

Deploying and implementing business strategy and sustaining results after the completion of key projects is more achievable when functional teams are managed effectively.

Continuous Improvement Culture

Good team management facilitates the development of a culture of continuous improvement within the organization. By creating habits of following performance indicators, identifying deviations from objectives, and defining countermeasures, teams can identify improvement opportunities on a daily basis. When teams are encouraged by their leaders to suggest improvements to their daily work, they realize that they are in a safe environment where ideas and suggestions are valued, promoting a cultural transformation.

Agile Teams

Structured management plays a fundamental role in creating agile teams. Teams, by having effective management, where leaders are close to the Gemba (field) and the business, develop agile collaboration and gain a greater ability to respond quickly to changes and deliver high-quality results.

Agility is facilitated by clear responsibilities, open and transparent communication, clear goals defined, efficient planning, and the growth of autonomy and continuous improvement capacity of teams.

Consistent Processes and Results

A good team management model enables to create consistent processes and results. Teams that work in a structured way to improve and standardize activities and monitor indicators frequently develop consistent processes essential to achieving the required output efficiently and with quality.

Good management can be expected to directly impact variability reduction and the positive evolution of key team indicators.

The Pillars of Effective Team Management

The KAIZEN™ Institute has developed a program called KAIZEN™ Daily (KD), aiming at organizations to improve the performance of their natural teams across the entire organization.

The goal of DK is to create leaders who develop their teams to be autonomous and capable of maintaining and improving their processes and work areas daily, contributing to a Continuous Improvement culture.

DK activities differ from project activities in that they are not time-limited. They are a continuous improvement activity carried out by all-natural teams.

DK leaders are leaders of natural/functional teams at all levels of the organization. Starting from implementation in the Gemba teams and ending with management leaders, DK involves everyone, every day, in all areas of the organization.

In this process, leaders play a crucial role in engaging the team, consolidating new work methods, valuing their employees’ ideas, and guiding the continuous improvement process.

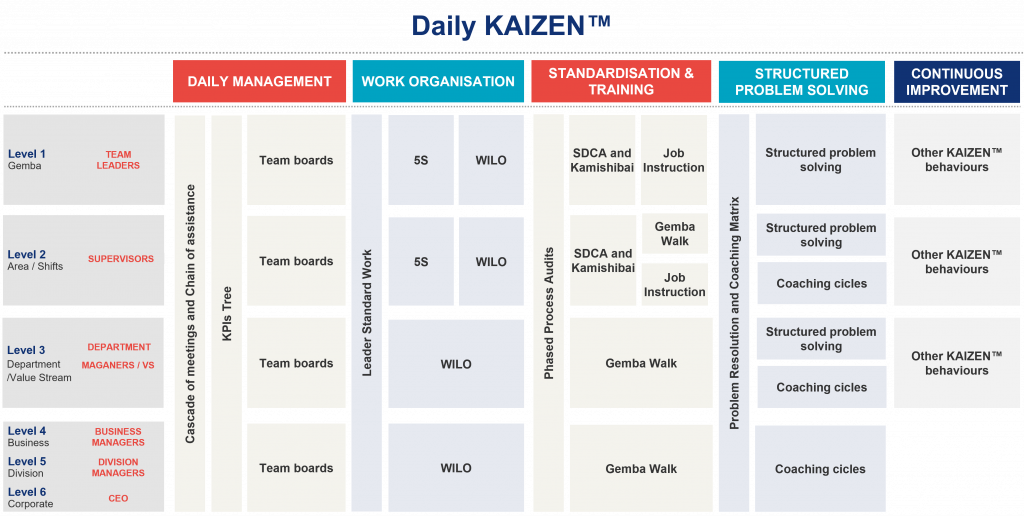

The Daily KAIZEN™ program consists of 4 levels.

Daily Management – The Key to Continuous Improvement

Daily Management aims to provide the leader with a set of tools for organizing and managing their team in their daily work. The goal is to align performance and objectives, have a greater ability to react to deviations, and optimize the time for discussing improvement opportunities – enhancing their deployment and improving team communication and motivation.

A key tool in the first level of Daily KAIZEN™ is frequent meetings between leaders and their teams. In these meetings, a set of standardized information is analyzed, referring to the team’s performance, organization, and improvement activities. The data is usually displayed on a physical or digital board. The main objectives of these meetings are to streamline the execution of the work plan, analyze deviations in indicators, and identify countermeasures for these deviations.

Level 1 of DK aims to identify the team’s key behaviors to sustain and improve them over time by defining tracking metrics and acting quickly whenever necessary. This organizational change also allows all teams to be involved in the improvement and thus develop a culture of continuous improvement.

Work Organization – Work Routines and Spaces Organization

The second level of Daily KAIZEN™ aims, on the one hand, to analyze the current work routines of leaders and help build a vision of greater added value and, on the other hand, to make workspaces (physical, transactional, and virtual) more organized and easier to work in.

To improve work routines, we start by studying the agendas of team leaders and then move on to improve and standardize them. To analyze the leaders’ agenda, a tool called WILO – Week In the Life Of – is generally used, which is a detailed record of a typical week in the life of a leader, including all types of professional activities. These activities are then classified as being of added value or waste. The improvement involves eliminating or minimizing all low-value-added tasks and replacing them with team management and improvement tasks.

The primary goal of level 2 is to develop leadership skills, minimize firefighting activities, and promote leadership by example. By following a structured workday to deliver the highest value-added tasks in a standardized and consistent way, leaders are promoting these behaviors within their teams.

The second goal of level 2 is workspace organization. The adjustment of physical or digital work areas facilitates the change in people’s behaviors and allows to eliminate time spent looking for materials or data, improve data management, and reduce costs through better use of materials and equipment.

The tool used to organize spaces is called 5S and is a work organization method consisting of 5 steps starting with the letter “S” in Japanese. It can be applied to physical or digital spaces. Although it may seem like a basic methodology, it allows managers to understand if the organization has the discipline to comply with the standards that guarantee the expected results. A team that cannot keep the organization of its workspace is hardly prepared to improve and comply with other standards.

Standardization & Training – Driving Efficiency and Compliance

Level 3 aims to introduce routines of analysis and work standardization, which should be implemented in each team to eliminate waste and variability continuously.

First and foremost, this third level focuses on standardizing and improving existing methods, create or update standards, and train employees. The standardization of activities is crucial, as standards promote consistency, serve as a reference for identifying deviations, ensure the preservation of knowledge, encourage team versatility, and form the foundation for audits.

For standards to be deployed effectively, the methodology of work instruction must be taught to leaders. This training tool allows the learning curve to be vertical and the variability of the results to be reduced.

Another matter addressed on this third level is implementing a Kamishibai system—a visual management system based on cards that aim to reinforce work methods, working as an audit. A board is created with cards; each has two sides with the same content but different colors. Green shows that everything is in order, and red that there is at least one non-compliance. The visual display of Kamishibai cards allows anyone to assess the state of the area quickly. Kamishibai cards can be used by employees at different levels of the organization.

Finally, we are also working on the implementation of Gemba Walks. A Gemba Walk is an activity in which the organization’s leaders visit the teams’ workplace to see daily operations, verify compliance with standards, interact with team members, and identify improvement opportunities. Gemba Walks are a standardized way of connecting leaders with the Gemba so they can know what is really happening there; it aims to reinforce behaviors and habits that leaders consider relevant for business success. In a way, it is a process confirmation. Gemba Walks are carried out with an audit mindset, with the support of Kamishibai cards or checklists, and should follow fixed routes and be carried out by various levels of management.

Structured Problem Solving – Tackling Complex Issues

The primary objective of Level 4 is to establish routines for improvement and problem anticipation within natural teams, thereby fulfilling the ultimate purpose of Daily KAIZEN™: to empower teams to sustain and improve their processes daily.

The content of this level is two-fold. On the one hand, teams are trained to use structured problem-solving tools; on the other, they are trained to approach more complex problems, the Improvement Kata.

To fully solve problems, a structured problem-solving approach should be adopted, seeking to identify and solve root causes, preventing their recurrence. The 3C methodology (Case, Cause, and Countermeasure) is used for more straightforward issues, while for more complex problems, Kobetsu KAIZEN™ is applied.

The other topic addressed at this level is the Improvement Kata, to make the continuous improvement process consistent among natural teams and establish new routines of coaching and improvement. With the Improvement Kata, improvement is focused on a target state, resulting from a challenge. Teams work on eliminating obstacles, iteratively incorporating lessons learned from the previous step. This improvement process is supported and sustained by coaching sessions conducted by a senior member of staff: Kata Coaching.

It’s important to note that daily management meetings are used to identify improvement opportunities, but problem-solving should not be discussed in detail in these meetings. When there is a need to solve a more complex problem, a problem-solving meeting should be scheduled. Structured problem-solving should address complex issues identified in daily management, which require more time to assess and identify the root cause.

Implementing a Team Development Program – The KAIZEN™ Approach

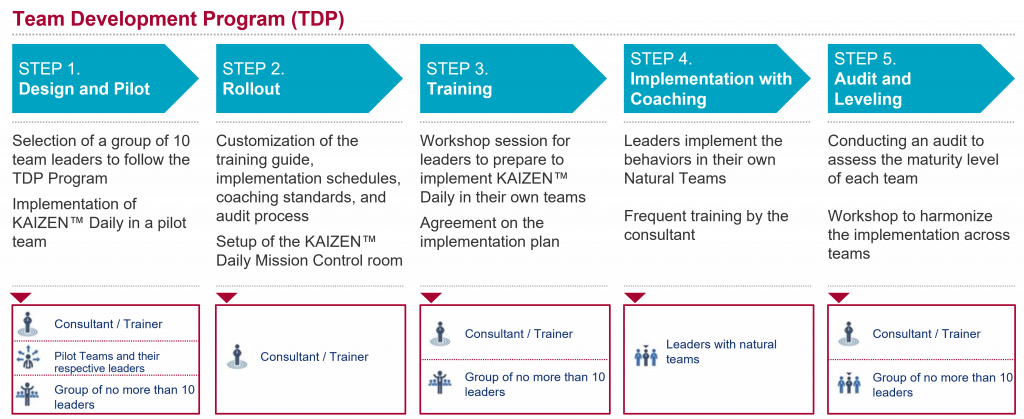

The Team Development Program, or TDP, is a step-by-step program to implement a complete Daily KAIZEN™ system in all teams of a value stream or department teams. The goal is to train team leaders and supervisors to implement Daily KAIZEN™ in their teams. This program follows a standardized 5-step approach that allows organizations to implement DK with sustainable results. This sequence is repeated for each level of Daily KAIZEN™️.

Design and Prototype

The first step of the TDP is to conduct a pilot workshop. With this workshop, we are aiming to empower team leaders in the practical implementation of a specific tool or methodology. The second objective is to demonstrate the effectiveness of this concept within the organization, collecting examples that will allow customizing the implementation guide to be used by the remaining teams. For the pilot workshop, a group of 8 to 10 leaders is selected, who will be implementing a specific level of Daily KAIZEN™ in the pilot team. The activities begin with the training of leaders, followed by implementation in the Gemba.

Program Deployment Preparation

The DK implementation support guide is customized in this second step with respective implementation agendas, coaching standards, and the audit process.

The implementation support guide includes a step-by-step explanation and real examples of applications collected during the pilot workshop.

In this second step, the Daily KAIZEN™ Mission Control room is also set up. In this space, all relevant information is gathered, allowing us to track the DK program implementation in all teams.

Team Leaders Training

In the third stage, a workshop session is held for the leaders to get ready to implement Daily KAIZEN™ in their teams. In this session, the result of the pilot workshop and the implementation support guide are presented, and questions that may arise are addressed.

The DK implementation plan is also agreed upon with all involved leaders.

Implementation with Coaching

In the fourth step, the leaders implement the defined initiatives and promote behavioral changes in their natural teams, following the implementation support manual and the established schedule.

Leaders train their teams on the job, implementing the agreed activities, and receiving coaching sessions and expert support to answer any questions and ensure expected results are achieved.

Audit and Levelling

Finally, an audit is conducted to check the maturity level of the implementation in each team. Subsequently, a workshop is held to level the implementation among the teams, share success stories, reinforce critical behaviors, and recognize achievements. The goal is to promote a learning and collaboration environment where teams can share experiences, improve, and celebrate the results achieved.

The Relationship Between Daily KAIZEN™️ and Strategic Initiatives

Daily KAIZEN™️ and Strategic Initiatives and Projects stemming from the Hoshin are mutually beneficial. Strategic initiatives require Daily KAIZEN™️ to transform new standards into daily practice, ie. to sustain disruptive leaps. We can say that today’s Hoshin is tomorrow’s standard work. On the other hand, an organization that only applies Daily KAIZEN™️ may be able to eliminate variability and make minor improvements. Still, it will hardly generate double-digit annual growth, as it does not act on the organization’s cross-functional processes.

Daily KAIZEN™️ and Project KAIZEN™ must work together for companies to achieve their target growth.

Still have some questions About Team Management?

What is Gemba?

Gemba is a Japanese term referring to the place where real work happens and where value is added. The philosophy behind going to the Gemba suggests that the best way to understand a process and identify opportunities for improvement is to go directly to the place where it occurs.

What is the 5S Methodology?

The 5S methodology is a management and workplace organization approach, whether physical or digital, originating from Japan. The 5S are a set of five principles or steps where each “S” represents a Japanese word describing an action or concept related to organization and discipline:

- SEIRI (Sorting): separate what is necessary from what is not;

- SEITAN (Set in Order): organize items visually and efficiently;

- SEISO (Shine): inspect areas, ensure good working conditions, and restore original conditions;

- SEIKETSU (Standardize): standardized to maintain the conditions established with the first 3 “S”;

- SHITSUKE (Sustain): enforce and improve the standards of space organization.

What is the Job Instruction Methodology?

Job Instruction (JI) is part of TWI (Training Within Industry), a training methodology developed during World War II in the United States. The main objective of JI is to provide a structured method for training employees in their tasks, ensuring they acquire the necessary skills to perform the work efficiently and consistently. The Job Instruction method is divided into two phases: preparation and training.

What is the 3C Methodology?

The 3C problem-solving methodology, also known as 3C’s Problem Solving, is a structured process for identifying and effectively solving problems. This methodology consists of 4 steps:

- Case: problem definition;

- Cause: analysis of the problem’s causes;

- Countermeasure: Identification of corrective actions;

- Validation: Verification of solutions.

What is Kobetsu KAIZEN™?

Kobetsu KAIZEN™ is a structured problem-solving methodology. The term “kobetsu” means “specific” in Japanese, and “kaizen” means continuous improvement. The methodology is structured in 9 steps:

- Define the challenge;

- Check the current state;

- Define the target state;

- Investigate root causes;

- Design solutions;

- Testing solutions;

- Update the action plan;

- Confirm results and standards;

- Evaluate and deploy.

See more on Team Management

Find out more about improving this business area

See more on People & Culture

Find out more about improving your organization