Introduction

KAIZEN™, also known as continuous improvement, was born in Toyota after World War II by the company’s founders, the Toyoda family. There was a need to catch up with the West economically and, as such, KAIZEN™ took off as a company improvement effort.

KAIZEN™ was born in production before expanding into supply chain. Nowadays it is entering the growth areas of sales, marketing, and innovation.

The pioneer of ‘growth KAIZEN™’ is the Danaher Corporation, which strongly developed KAIZEN™ in growth areas (an expansion of operational KAIZEN™).

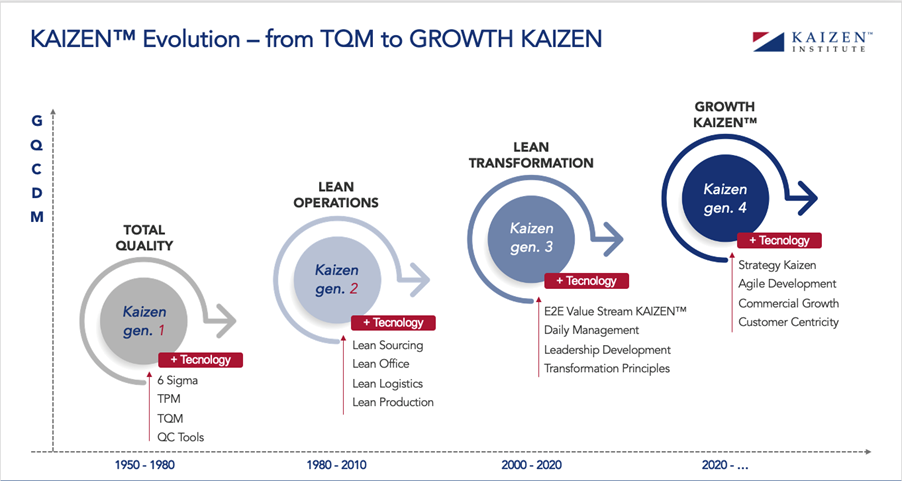

The following picture shows the evolution of KAIZEN™ since 1950:

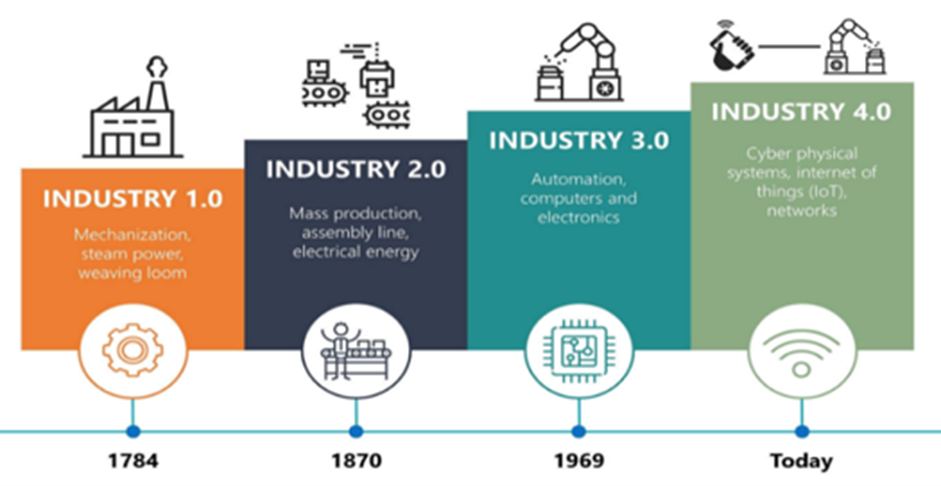

Today, another trend is receiving a lot of attention: technology, digitalisation and the internet revolution. In industrial companies, the term ‘Industry 4.0’ is commonplace, while in service areas the term ‘digital transformation’ has become ubiquitous.

Technology needs to be integrated with the KAIZEN™ management methodologies while growth KAIZEN™ is intimately linked to digital transformation.

KAIZEN™ Generation 1 (1950-80): Total Quality as the Birth of KAIZEN™

After World War Two Japan was devastated and the US Army offered help to rebuild industrial companies. American experts like Juran and Deming taught the Japanese how to improve quality. This was KAIZEN™ Generation 1 with a focus on Total Quality Management (TQM). In fact, the first book about KAIZEN™ written by Masaaki Imai (founder of Kaizen Institute) in 1984 was about the TQM movement in Japan.

It was the time of Quality Control (QC) Circles, Total Productive Maintenance (TPM) and the start of Six Sigma (although the term ‘Six Sigma’ came later, Statistical Process Quality Control started at this time).

Meanwhile, technology also developed a lot. In terms of automation, this was the era of Industry 3.0 (see picture below) and the focus was on how to automate the machine cycle time to free operators, so that they could work on more than one machine. This was also the time of Enterprise Resource Planning (ERP) software based on Manufacturing Resource Planning (MRP) algorithms.

The connection between KAIZEN™ and technology is that the former deals with how to organise people and process, while technology deals with how to do things faster and simpler. Technology is an enabler of people and process, and should always be designed after the KAIZEN™ of people and process (more on this in a future article).

KAIZEN™ Generation 2 (1980-2000): The Lean Operations Toyota Production System (TPS)

By the 1980s Toyota had perfected KAIZEN™ to focus on the creation of flow with KANBAN and pull flow algorithms. This was the work of Taiichi Ohno who invented a new way to organise production and internal logistics. KAIZEN™ was by then a new Production System where the emphasis was on small batch agility and all automation was secondary to this principle. A very fine KAIZEN™ book explains what Lean KAIZEN™ is and the difference between resource efficiency and flow efficiency.

It was also at this time that a study from MIT about the automotive industry showed the superiority of the Toyota Production System (“The Machine that Changed the World”) where some of the authors coined the term Lean to describe the TPS.

This was the time of operational excellence based on the TPS principles of flow and resource efficiency, and, of course, incorporating all the improvement tools used in KAIZEN™ Generation 1.

Because of the success of the Toyota Production System many companies started implementing a similar operational efficiency system that usually took the name of the company (e.g., the Bosch Production System).

KAIZEN™ Generation 3 (2000-20): How KAIZEN™ Evolved to Lean Transformation

Soon it was clear for many companies that KAIZEN™ could not only be a production system. For it to succeed, leadership teams and the chain of command needed to be completely engaged.

The term Lean transformation was being used to implement KAIZEN™ in natural teams for the implementation of world class KAIZEN™ leadership behaviours. This is also called Daily KAIZEN™ for natural teams, and the aim was to move to a ‘command and control’ leadership style to a coach and empower individuals.

During this time we also witnessed the rise of the internet. We entered the era of connected machines and connected customers with Industry 4.0 and more powerful digital solutions starting to appear. But KAIZEN™ and the management culture of continuous improvement continued to develop.

We also saw KAIZEN™ being expanded to service companies, offices and other transactional areas including government and shared service centres.

KAIZEN™ Generation 4 (2020 – ): The Era of Growth KAIZEN™

The goal of KAIZEN™ is to change the company for the better, so it must be a business-wide effort. When we talk business, we cannot only consider the operational side of the business (a.k.a. the supply chain). Therefore, it became clear that KAIZEN™ should be expanded to growth areas (departments and processes that impact more direct sales), and not only sales, but also the profitability and attractiveness of the value proposition (product and service).

The Danaher Corporation was the first company to understand that KAIZEN™ is a business-wide effort. There is a magnificent case study on the Harvard Business Review that explains this very well.

And so the era of growth KAIZEN™ started with management systems and tools that can streamline and improve sales and innovation. It is herein that KAIZEN™ can help you to better understand markets and consumers, how to attract greater interest, how to convert more leads into customers, and how to generate more innovative ideas and accelerate time-to-market. All of this is growth KAIZEN™ and in further articles we will explain the What´s and How´s of the growth KAIZEN™ methodologies.

Now that we are living in the age of the internet, and digitalisation is advancing across all sectors, we will also divulge why some processes need to based on digital platforms and how to integrate KAIZEN™ with automation, IT and advanced analytics.

Conclusion

The KPI’s of growth KAIZEN™ are sales, marketing/sales conversion rates, customer retention rates, customer satisfaction, time-to-market, sales of new products, innovation and all funnels related to growth (marketing, sales and retention).

The goal is to improve with KAIZEN™ and have a continuous impact on growth and profitability (together with operational excellence). Stay tuned for more articles about growth KAIZEN™.

#strategy and leadership #culture and organisation

See more on Culture & Organisation

Find out more about improving this business area