CEOs are essential in guiding their companies toward continuous improvement and success. This article reveals how a transformation journey can shape strategic planning, starting with the CEO’s engagement in gathering the Voice of the Customer. We’ll explore Value Stream Analysis, Kaizen Events led by top management, and how Daily Kaizen practices can cultivate a culture of improvement.

However, this exploration extends beyond theoretical concepts. The turnaround story of GE under CEO Larry Culp is a great example of the powerful impact brought by this approach. By adopting Kaizen and lean manufacturing principles, GE improved its operations and fostered a culture where everyone can make a difference.

Dive into this article for actionable insights and inspiration. Discover how embracing a continuous improvement mindset can lead to remarkable organizational change and position your company for long-lasting success.

CEO Voice of the Customer To Develop a Value-Based Strategy

CEO Voice of the Customer (VOC) is a strategic approach where top-level executives, particularly CEOs, actively engage with and listen to customer feedback to shape their company’s strategies.

CEO VOC can take multiple forms, such as direct interviews, Gemba visits, or participating in customer support calls. CEOs can gain unfiltered insights into the market, customer satisfaction, and the perceived value of their products and services by directly hearing from customers. This firsthand knowledge can be invaluable in making strategic decisions.

Showing that the CEO cares about customers’ opinions and is willing to make changes based on their feedback can also significantly enhance trust in the brand. Customers feel valued and more likely to maintain a long-term relationship with the company.

CEO VOC positions customer insights at the heart of business decision-making. This approach ensures that companies remain closely aligned with their customers’ evolving needs, securing a competitive advantage in the market.

VOC-based Hoshin To Plan a Business Strategy Aligned with Customer Needs

VOC-Based Hoshin is a strategic planning methodology that integrates customer feedback (Voice of the Customer) into an organization’s strategic planning and execution process. This approach is about mixing customer insights with the organization’s goals and activities, ensuring that every action is aligned with customer needs and expectations.

VOC-Based Hoshin starts with a deep dive into understanding where the company currently stands regarding performance and ambition. Following an introspective phase, the process shifts towards external analysis, blending insights from various sources – CEO VOC, market trends, competitive dynamics, and internal capabilities – to identify strategic opportunities. This data lets the organization understand what it takes to be a winner in its market, revealing the capabilities needed, the gaps to be bridged, and the strategic initiatives that should be prioritized. Then, the top X matrix must be defined, identifying the annual breakthrough goals, priorities, improvement targets, and owners.

VOC-Based Hoshin goes above traditional strategic planning by defining an effective growth plan for the business that is aligned with customer needs.

Value Stream Analysis To Plan Effective Business Impact Strategies

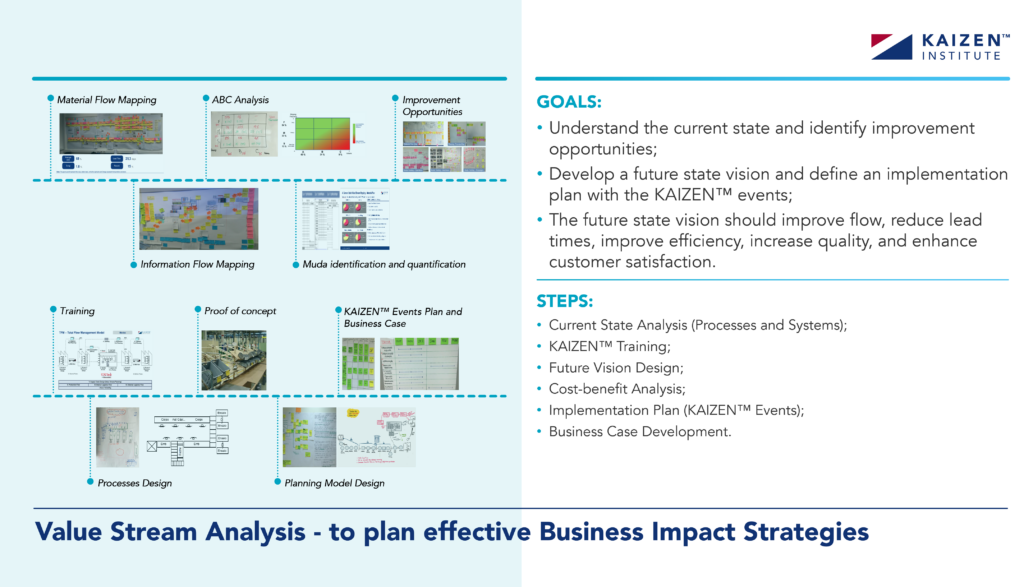

Value Stream Analysis (VSA) is a tool used to optimize processes, focusing on delivering maximum value to the customer while minimizing waste. It looks at the materials and information flow from when a customer request is received to the delivery of the final product/service. VSA helps organizations understand their current operations, envision a future state, and plan actionable steps to reach their objective.

The process begins by mapping the current material and information flow state, followed by training in KAIZEN lean principles.

After thoroughly understanding the current state, the focus shifts to designing the future state—a vision of how the value stream should ideally operate. It aims to improve flow and eliminate inefficiencies, resulting in reduced lead times, enhanced quality, and increased customer satisfaction.

The transition from the current state to the future state is defined through a detailed implementation plan with KAIZEN™ events. These events are focused, short-term projects that bring together cross-functional teams to implement changes in a specific value stream area.

Finally, the business case outlines the expected benefits, costs, and return on investment, acting as a roadmap for stakeholders and securing their support for the implementation phase.

The overarching goal of Value Stream Analysis is to create a seamless, efficient process that delivers value to the customer at every step.

CEO Kaizen Week To Lead by Example in an Agile Way

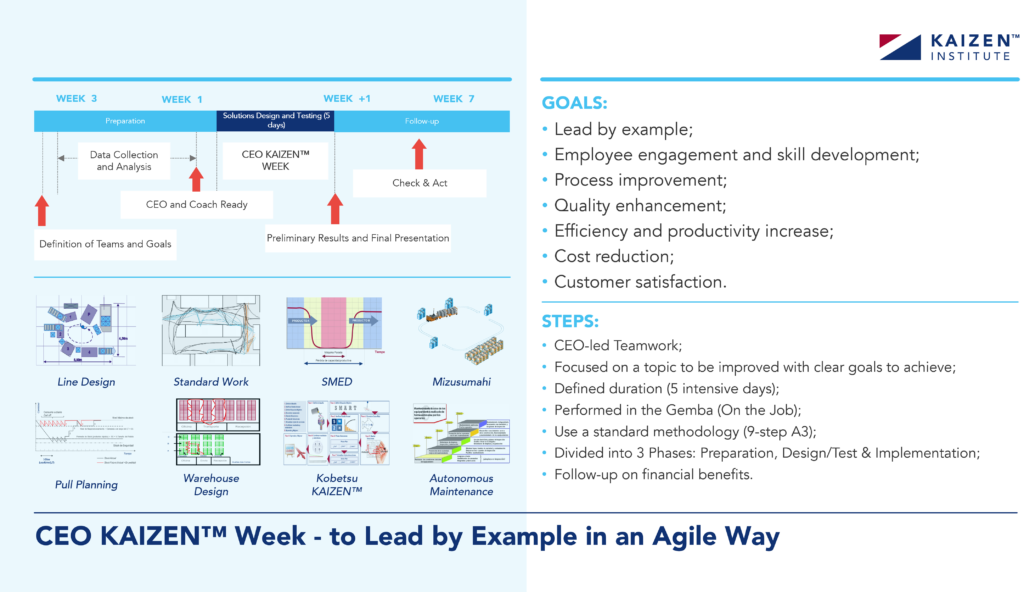

A CEO Kaizen Event represents a short-term initiative led by an organization’s highest levels of leadership to instigate significant improvements within a specific business area. What sets a CEO Kaizen Event apart is top management’s direct, hands-on involvement in identifying, analyzing, and solving operational challenges. The process selected to improve typically results from a Value Stream Analysis.

The event is structured into three phases: preparation, solution design/testing, and follow-up. The solution design and testing phase typically consists of a five-day intensive workshop with a team led by the CEO or another top executive. This team dives deep into the Gemba (where work happens) to improve a specific topic. These events are designed to deliver measurable results, including increased efficiency and productivity, reduced costs, and improved customer satisfaction.

Ultimately, a CEO Kaizen Event is more than a process optimization exercise. It is a powerful demonstration of leadership’s commitment to driving positive change, an opportunity to engage and empower employees at all levels, and a strategic tool for aligning the organization’s operations with its objectives and customer expectations.

3P – Production Preparation Process To Accelerate Process Transformation

The Production Preparation Process (3P) is a workshop designed to optimize manufacturing by minimizing waste, enhancing productivity, and ensuring that production systems are agile and responsive to demand fluctuations. It is one of the preferred events at the CEO KAIZEN level.

Understanding demand and aligning production capacity accordingly are key in 3P workshops. This involves analyzing demand and calculating the takt time for each family. Another key element is developing a process graph, a visual representation of the most logical assembly order and each operation’s duration. After this, it is time to perform line balancing and discuss different macro line layout options, selecting one or two to test.

Simulating the production environment before actual implementation is one of the most essential aspects of 3P. This involves creating physical mock-ups (cardboard engineering) to test and refine the production layout and process flow. These simulations are beneficial for finding problems that might not be obvious when planning.

The workshop concludes with implementing changes in the line and updating visual management and standards.

The Production Preparation Process is an event that involves employees with design and testing to create manufacturing environments that are efficient, flexible, and aligned with customer demand.

Mission Control To Manage Improvement Programs Effectively

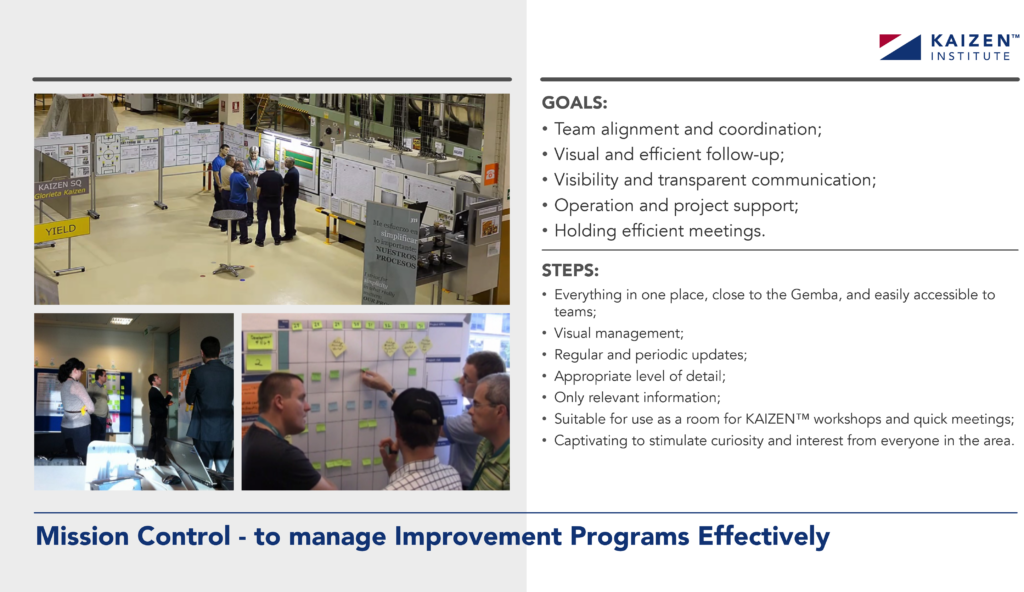

Mission Control, also known as Obeya Control, is a centralized, visual management system that serves as a hub for coordinating and tracking the progress of various projects or events within an organization. Mission Control is designed to bring critical information and stakeholders together in a single, physical, or virtual space, facilitating better decision-making, alignment, and collaboration. This approach is effective in supporting KAIZEN™ initiatives and other continuous improvement efforts.

The essence of Mission Control lies in its ability to consolidate vast amounts of information into easily digestible, visually engaging formats. Doing so ensures everyone understands the current situation, the challenges, and the progress toward goals. Centralizing crucial information facilitates regular and meaningful updates, ensuring the displayed data is up to date and precisely what the team needs to drive decisions.

Mission Control manifests the belief that well-informed teams, supported by clear, accessible information, are better equipped to navigate challenges, seize opportunities, and achieve breakthrough results.

Daily Kaizen To Develop Leaders, Sustain Improvements, and Create a CI Culture

Daily Kaizen is an approach to continuous improvement implemented across all organizational levels and teams. It aims to shift from the traditional management model, where reactive firefighting is prevalent, to a continuous improvement culture characterized by problem-solving, visual management, standardization, and team development.

Daily Kaizen trains the leaders to regularly monitor key performance indicators (KPIs), define countermeasures, and develop better work standards with their teams.

Daily Kaizen implementation follows a sequence of steps, typically starting by establishing team boards displaying KPIs and other relevant information alongside regular meetings based on these boards. The next phase involves optimizing space through 5S implementation. Next, processes are standardized to minimize variability and ensure quality. The final step involves structured problem-solving.

Daily Kaizen is vital for fostering an organization’s continuous improvement culture. It encourages everyone to contribute to improvements and ensures that improvements made during Kaizen workshops are sustained and further developed over time.

Larry Culp’s Kaizen Transformation at GE

In 2018, GE faced challenging financial issues, a declining market share, and negative public perception. GE brought in Larry Culp as the new CEO, who had fresh ideas to turn things around. Larry Culp’s leadership at GE has been marked by a transformative push toward a lean manufacturing model, starkly contrasting the company’s previous, less efficient practices. This model focuses on making parts delivery more efficient, ensuring high quality with minimal waste, and relies on everyone’s contributions to continuously enhance operations, especially input from factory floor workers.

Under Culp’s leadership, GE has been actively engaging in Kaizen events, where personnel, managers, and sometimes consultants worked together to improve manufacturing processes based on observations from the production area. This practical, hands-on strategy has led to notable improvements. Culp values open communication and seeing challenges as opportunities, pushing for a culture where issues are openly addressed and solved, fostering an environment of continuous improvement and accountability.

The success of this Kaizen-driven turnaround at GE is primarily due to the strong commitment from Culp and the top management and the active participation of employees directly involved in the processes. This has not only led to better solutions and operations but has also improved morale among employees. With Kaizen at its heart, GE’s story under Culp shows how focusing on continuous improvement can significantly benefit a large, complex company, turning difficult situations into success stories.

“Use Kaizen to double profits and halve costs.”

See more on Strategy Deployment

Find out more about improving your organization

See more on People & Culture

Find out more about improving your organization