The 5 Whys analysis

Why do many continuous improvement transformations fail?

If you ask this question to Masaaki Imai, the father of Kaizen, he will probably answer that there are three reasons: the 1st is top management commitment, the 2nd is top management commitment, and the 3rd is top management commitment.

Why is there a lack of Top Management Commitment?

This is the 2nd ‘Why’ of a good, old-fashioned 5 Whys analysis.

I believe that the Top Management does not know how to deploy continuous improvement properly, despite knowing its benefits, because they have seen it in pilot areas and benchmark CI companies like Toyota or Danaher.

But they misunderstand and underestimate the changes required in their own process of managing the company.

Why does the top management misunderstand and underestimate the changes required in managing the company?

This is the 3rd why in our analysis. Well, they think continuous improvement is just a set of tools (like the Toyota JIT house or the TPM 7 pillars house) and that if they hire a continuous improvement manager to teach people how to use these tools, they will use them.

So why do people refrain from using the Continuous Improvement toolbox?

People only use tools if needed to achieve their objectives, and the Top Management is good at proposing challenging goals. The problem is that the objectives are usually related to maintaining control over daily issues – firefighting – or implementing projects that compete with using the tools – the so-called strategic projects. Time and energy are limited, and choices need to be made.

This brings us to the last question in our analysis.

How can we solve daily problems and implement strategic projects with the continuous improvement toolbox?

The answer is that we need a good deployment standard clearly explaining the steps to solve daily problems and implement strategic projects. This is something quite different than a continuous improvement toolbox.

This is what we call a continuous improvement deployment process – the process owner is the Top Management, and they must be willing to change how they manage the company.

To complement the last sentence, continuous improvement managers must advise top management about the management processes to be implemented rather than the toolboxes that may be used.

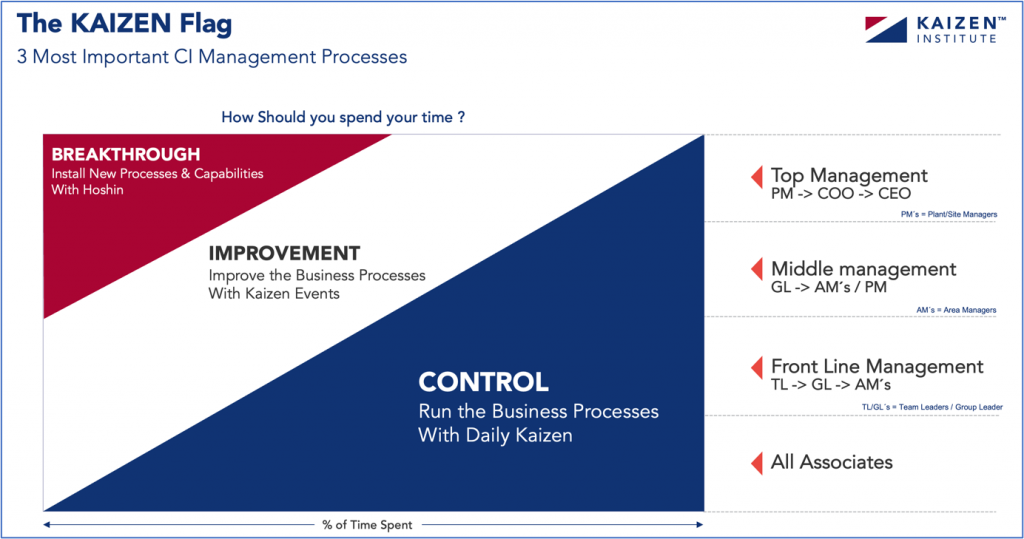

According to the KAIZEN™ flag below, what are the right processes for continuous improvement deployment (or management)?

The golden standard for KAIZEN™

The golden standard for “control” preventing firefighting and driving small improvements

The first sub-process of the continuous improvement deployment process is the step-by-step explanation of how to deal with control to avoid firefighting.

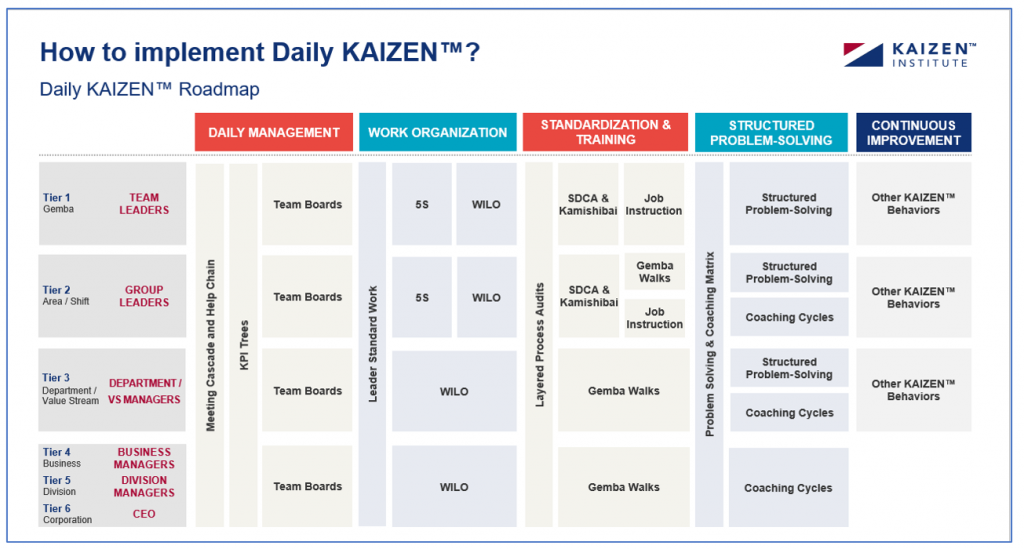

This is the daily management process (or Daily KAIZEN™) that must be implemented by every team leader at all levels, requiring a change in how leaders manage their teams.

In any company or organization, there is a team hierarchy – the company is a team of teams – composed of natural teams ranging from Top Management teams to Front Line Management – the team leader managing a team of workers.

The team leaders must know how to control the processes under their supervision to avoid firefighting. This can be achieved by following KPIs, solving deviations, and engaging in a help chain process.

The continuous improvement ‘Control’ process should be taught and implemented in all teams by the team leader at all levels.

Will they use continuous improvement tools? Obviously, the ones they need to control and avoid firefighting. These tools will be part of the process, but the tools themselves are not the process.

Before implementing Daily Management, a thorough check of the organizational blueprint is required to design the right span of control and define the basic training needed for team leaders.

Furthermore, each team needs to carefully discuss its mission and vision and the appropriate KPIs for control. Problem-solving tools will work if the team leaders have a clear vision of what the team needs to achieve.

This applies to all teams. It is a network of teams coordinated to control and contribute to the business’s success by avoiding problems and making small improvements. The following image helps to understand the need for a process to deploy Daily KAIZEN™.

The golden standard for “improvement”, solving cross-functional challenges, and implementing strategic initiatives

In the KAIZEN™ flag, the white middle strip represents “improvement”.

“Improvement” means solving problems that extend from one team to another, where the root cause may be upstream, and the problem may be noticeable in a team downstream.

We need a way to apply KAIZEN™ by engaging several teams. We also need a way to implement breakthrough changes or mid-sized process improvements and engage various temporary project teams with all capabilities to achieve it.

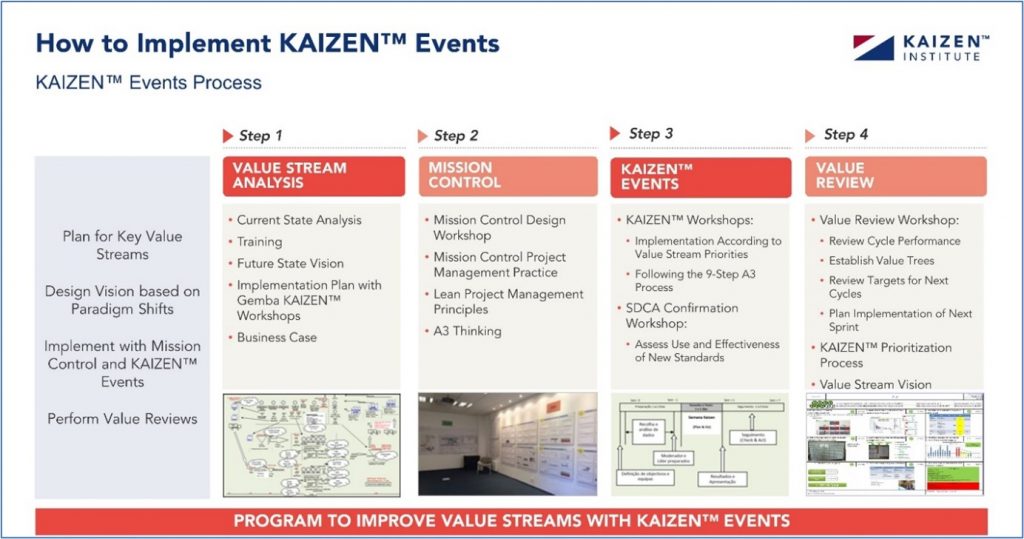

We must also master the KAIZEN™ Event process, which requires changing how leaders manage projects.

KAIZEN™ Events are a quick, sprint-based way to set up a project team to solve a complex problem or to implement a breakthrough solution to a need. Usually, these events should not take more than three months and must include preparation, intensive days for design/tests, and follow-up to implement actions.

Key people in the organization must learn and master how to do a KAIZEN™ Event or Sprint. The process is like Project Management using the Toyota way with a PDCA cycle followed by a SDCA cycle – improve first, then standardize.

Why should a company develop a process instructing how to do KAIZEN™ Events?

Mastering KAIZEN™ Events is the way to develop the “muscle” needed for further significant changes, such as the breakthroughs to be defined by Top Management (the strategic initiatives). We will talk about this in the next chapter.

Practicing KAIZEN™ Events is the way to master the process. The best CI companies usually follow the rule of 1 event for every ten people in the organization – the 1/10 rule, which means that if the company has 100 employees, there should be at least 10 KAIZEN™ Events per year. It is just a matter of doing it – practice turns into perfection. Check the process in the following image.

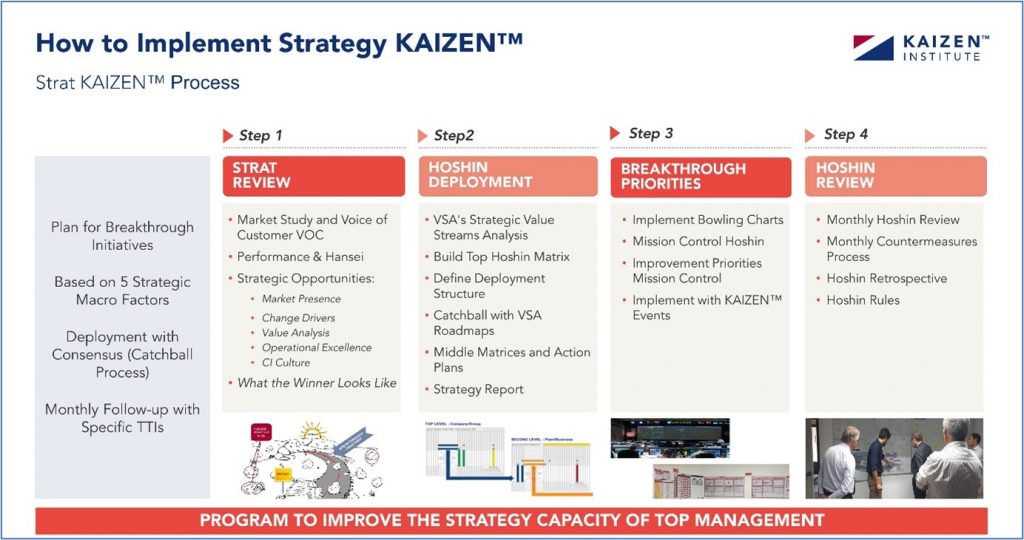

The golden standard for “breakthrough”, planning and deploying the company strategy (H3)

The red strip in the KAIZEN™ flag represents “breakthrough”.

Some people also call it the innovation process, and others say this is the process for major strategic improvements.

A straightforward process is needed, with clear steps and standards. The primary owner of this process is Top Management and possibly the CEO – requiring a change in how Top Management does strategy planning and deployment.

So, what is a process? The answer is simple. A process is a repeated practice that people frequently follow according to standards that will yield good results.

A strategy planning and deployment process is the most important process for the company’s growth and survival. This process will coordinate people to create the new and innovative processes the company needs to thrive.

It must be done according to the PDCA cycles. Mastering the Strategy KAIZEN™ process is therefore mandatory for the company’s success. The best Strategy KAIZEN™ processes are standardized and are the most important continuous improvement deployment processes.

Check out this picture that describes the process.

Why is this continuous improvement? And why is this so important? It is a continuous improvement because it must follow some continuous improvement KAIZEN™ lean values & principles to work well and integrate the improvement & control processes for effective implementation and maintenance.

This process will set the priorities for the company (alignment). As an example, if the main strategic objective is to increase efficiency by implementing a world-class total productive maintenance house, then it will be clear to everyone from top to bottom that the way forward is to implement a TPM house – no doubts, and total commitment from management, top to bottom.

Now imagine a different main strategic objective, for example, increase efficiency by digitalizing maintenance. It is vague and likely to divert attention and may risk also automating waste. Not exactly the best way to increase efficiency. Perhaps Top Management would like to achieve efficiency by digitalizing processes, but the Maintenance Manager is told to implement TPM based on the CI model. This results in organizational misalignment, and neither tools will be effectively implemented.

Steps to solve the top management commitment issue

To solve the top management commitment issue, we must have a good process to do the following.

Step 1: A strategy planning & deployment process

A strategy planning & deployment process, following the PDCA & SDCA principles, to decide the best breakthrough objectives and align everyone on this quest (the big changes). We will use CI tools (houses) clearly integrated into a management process starting from the top.

Step 2: A process to perform KAIZEN™ Events

This is used to execute the strategic action plan made up of KAIZEN™ Events that will generate continuous improvement and solve cross-functional problems.

This process will create new standards, which will be the learning & training process to acquire new capabilities. We can also standardize our toolbox with the best tools that generate the best results and are considered the best practice for Yokoten (implement everywhere)

Step 3: A Daily Management KAIZEN™ process

The daily team management process to control the team’s KPIs and adopt new standards derived from KAIZEN™ Events. This will allow the detection of any deterioration that can lead to firefighting. Every team at any level needs this process.

Applying the KAIZEN™ tools

So, the Golden Standard is becoming clear and must follow the above-mentioned, as seen in the KAIZEN™ flag.

But what about the toolbox that we know and is represented on the Toyota or TPM Lean tools? This comes after the continuous improvement management process described in the KAIZEN™ flag.

We just need a management process to implement continuous improvement, and this management process will use tools – but the target is not using the tools by itself or making a house of tools.

Please avoid the house of tools from the beginning. Maybe after some time, you can launch a house of Yokoten tools, the most useful in the CI Deployment Management process.

When and if you arrive at this point, there will be no difference between your management practices and the continuous improvement KAIZEN™ lean models.

You will manage your company using the Lean KAIZEN™ Way, and Continuous Improvement will be your company‘s credo.

Ps: a good credo reminds people of why the business exists. It motivates and lifts their spirits. It’s a unifying force, a statement of shared values that allows your employees to understand why continuous improvement is important and to collaborate to achieve a consistently high standard.

Euclides A. Coimbra

Senior Partner & Managing Director

Kaizen Institute Western Europe

www.kaizen.com

See more on People & Culture

Find out more about improving your organization