Context

Like other organizations, schools face the challenge of ensuring flexibility without compromising process robustness. Principals, coordinators, and teachers seek solutions to build schools capable of producing extraordinary results, regardless of the context. Acquiring key skills and adopting a disruptive approach is essential to achieve this. This ensures high-quality education tailored to students’ needs while addressing challenges common to many educational institutions, including socioeconomic diversity, resource limitations, and modernizing teaching methods.

This case study dives into implementing tools and projects in a school setting in various educational institutions, involving over 600 students, 30 classes, and 70 teachers and staff.

The Challenge

Schools faced several problems that negatively affected the educational environment and the teaching process.

Diverse socio-economic contexts led to varying parental involvement and support levels, which often impacted students’ engagement, behavior, and academic performance. Additionally, poor interest and academic performance, especially in lower socioeconomic areas, were exacerbated by the lack of personalized learning approaches, rigidity in traditional teaching methods, inadequate learning materials, and limited access to technology.

The weekly teachers’ meetings were often messy and lengthy and did not have a structured and clear agenda. There were many delays from the participants and a significant absence of structure in identifying problem causes and developing solutions, resulting in unproductive discussions and poorly utilized time. Likewise, students did not use class time effectively, resulting in less productive learning.

These related problems resulted in a less efficient educational experience, where teachers and students faced daily difficulties preventing the teaching-learning process from being carried out efficiently.

- The poor student engagement, exacerbated by socio-economic factors and traditional teaching methods, resulted in low academic performance and widespread demotivation.

- Disorganized teacher meetings led to lost valuable time that could be used to plan and improve teaching practices.

- Furthermore, the poor use of class time, caused by frequent delays and constant interruptions, compromised the continuity and quality of teaching, making it challenging to maintain a focused and productive environment.

These problems created significant barriers to achieving the required educational goals, hindering students’ holistic development and the overall effectiveness of the educational process.

The Approach

Schools implemented a comprehensive solution using the Kaizen methodology to tackle these challenges.

The mobile app “KAIZEN GO” was developed to increase student engagement and academic performance. This app was designed to transform students’ educational experiences and make it fun and entertaining, creating a more engaging and motivating learning environment.

The app included several features that encouraged healthy competition between classes. One of these features was the ranking system, which displayed the accumulated points and rankings of the different classes. This fostered friendly competition and motivated students to climb the rankings.

Additionally, the app allowed behavior tracking and awarding points by teachers and operational assistants. This system gave students points based on their academic performance and classroom behavior. It helped monitor and encourage positive behaviors and adequate academic performance.

The app also included a calendar feature to assist in planning. This feature allowed the recording of upcoming tests and assignments, which helped students better organize and adequately prepare for their academic responsibilities.

Another important feature of “KAIZEN GO” was the merit-based scoring system. Additional points were awarded for exemplary behavior and participation in events, recognizing and rewarding outstanding students and thus promoting a culture of excellence and continuous effort.

The app also incorporated various gamification elements, such as quizzes, achievements, and badges. These elements made learning more dynamic and engaging, encouraging students to interact with the educational content in a fun and interactive way.

Through these features, “KAIZEN GO” created a more stimulating and effective learning environment, increasing student engagement and significantly improving academic performance.

Several other measures were implemented under the “Weekly Kaizen for Teachers” method to improve the effectiveness of the weekly teacher meetings.

An attendance and punctuality tracking system was introduced. This system was designed to encourage individual and collective responsibility. With this reinforced control, delays were significantly reduced, and effective meeting participation increased.

Additionally, a detailed agenda was created to guide the meetings. It allocated specific time for each topic, allowing for more efficient time management and ensuring discussions remained focused on the most important issues. Structuring meetings this way helped eliminate lengthy, unproductive conversations and concentrate efforts on problem-solving.

Another important measure was to assign a timekeeper role. This person was responsible for monitoring compliance with the schedule defined, ensuring that meetings stayed within the allotted time. This role helped maintain time discipline and avoid unnecessary extensions, making meetings more productive.

Visual management was also crucial in implementing the Weekly Kaizen for Teachers. Visual management boards were used to record occurrences and solutions clearly and visibly for all participants. This practice helped to understand the problems and the actions required, promoting more active and informed participation.

Finally, a specific space for writing down solutions was created. This space ensured all issues discussed during the meetings were followed up with actual and documented actions. Writing down solutions provided a clear record of the decisions made and steps to follow, ensuring the identified problems were effectively resolved.

These measures combined resulted in organized and productive meetings, with clear improvements in discussion structure and focus. Applying Weekly Kaizen for Teachers optimized the use of time during meetings and fostered a culture of responsibility, active participation, and continuous improvement among teachers.

Schools adopted Kaizen’s 3C Methodology to optimize class time and minimize interruptions. This approach was key in identifying and solving underlying problems that affected class efficiency.

The first stage of the 3C methodology involved identifying the problem and root causes. Using visual boards, issues and their causes were mapped in detail, allowing a clear and shared visualization of all challenges to be addressed. This mapping ensured that everyone involved, including teachers, students, and admin staff, fully understood the nature of the problems and committed to their resolution.

Next, a delay indicator monitoring system was implemented. This system aimed to reduce delays by recording and analyzing student arrival patterns. With precise data on delays, the school was able to identify the most common causes and develop strategies to mitigate them. The goal was to ensure classes started punctually, minimizing time lost at the beginning of each lesson.

The final stage of the 3C methodology involved implementing specific countermeasures to address the root causes. This included a series of actions aimed at both students and teachers. For students, behavioral changes were promoted to encourage punctuality and reduce interruptions during classes. For teachers, practices were introduced to help maintain classroom control and ensure continuous teaching without disruptions.

These countermeasures were designed to solve immediate problems and create an efficient and productive learning environment in the long term. Implementing these changes significantly improved class time management, effectively using available teaching and learning time.

The Kaizen 3C Methodology has proven to be an effective approach to tackling school challenges. Schools created a more structured and efficient learning environment by focusing on accurate problem identification, rigorous indicators monitoring, and targeted countermeasure implementation, benefiting both students and teachers.

Results

Implementing Kaizen to streamline education produced significant results in several areas.

Student Engagement and Academic Performance Improvement

The gamified mobile app “KAIZEN GO” positively impacted student behavior and engagement, with most classes showing improvements. One class had the highest quiz adherence rate (64%), indicating greater engagement.

Surveys revealed increased motivation and improved behavior, with the app receiving positive ratings from students and staff.

Improvement in Meetings

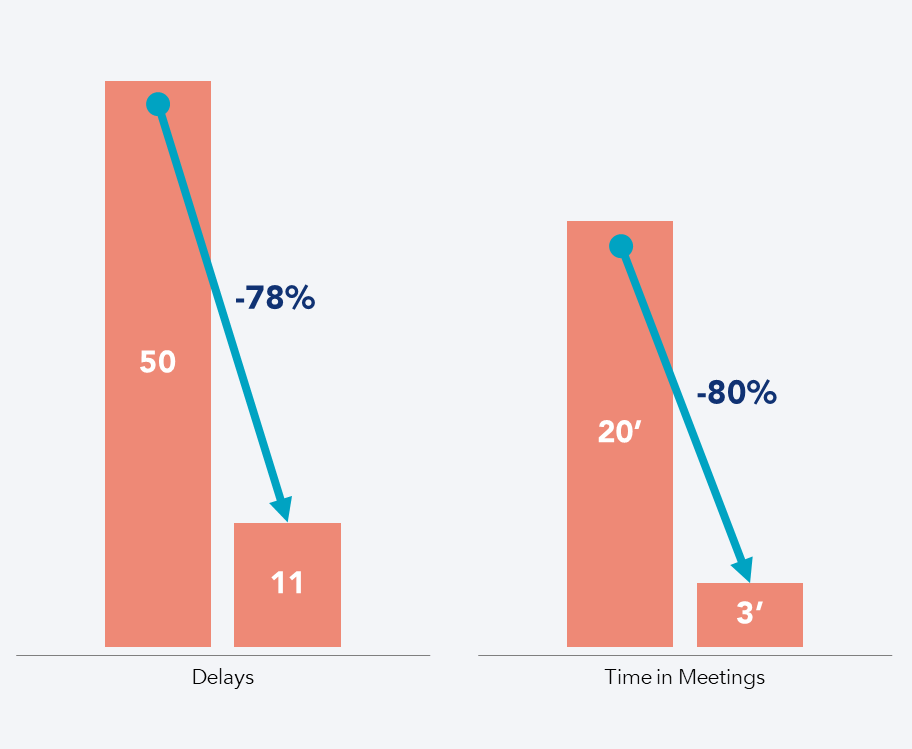

The introduction of Weekly Kaizen for Teachers significantly improved the meeting structure, with a 78% reduction in delays and an 80% decrease in the extra time needed to conclude meetings. Teachers reported better organization and focus in discussions, allowing for a more efficient use of time.

Increase in Productive Class Time

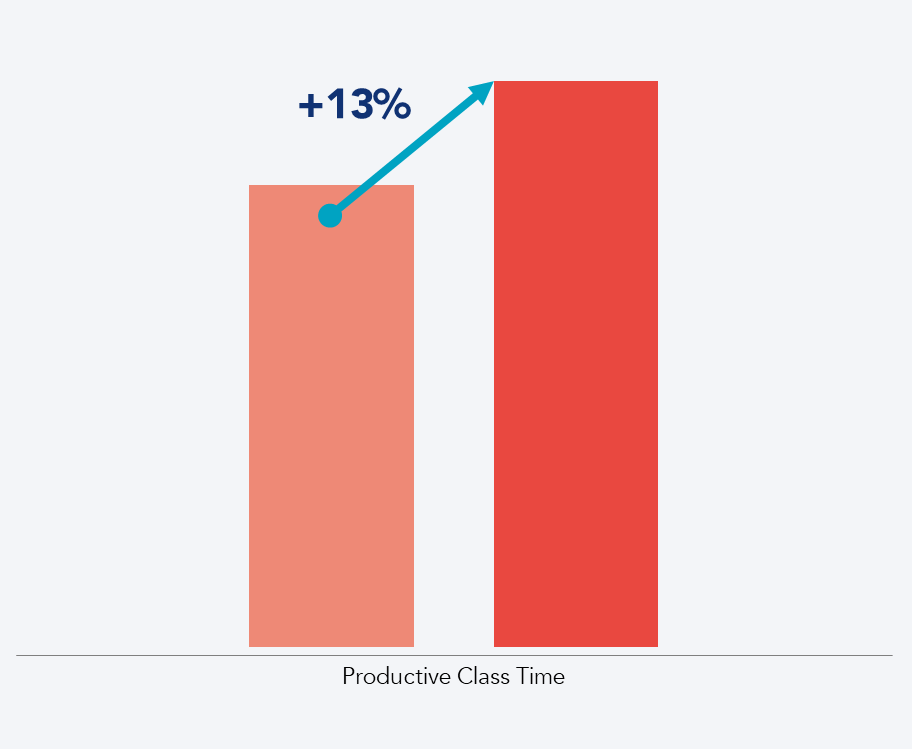

The Kaizen 3C method helped increase the time dedicated to teaching during classes by 13%. In addition, students were empowered with problem-solving techniques, leading to favorable behavior changes and a greater appreciation for punctuality.

Kaizen as a Driver of Transformation in Schools

Applying Kaizen successfully addressed educational institutions’ challenges, significantly improving time management, student engagement, and academic performance. Kaizen’s structured and continuous approach effectively transformed the school environment, underlining the importance of innovative solutions and continuous improvement in promoting a culture of efficiency and effectiveness. This case study demonstrates how a comprehensive solution can benefit the entire school community, creating a more productive and engaging teaching environment.

See more on Improvement Projects

Find out more about improving this business area

See more on People & Culture

Find out more about improving your organization