The Company

The Company, a major Western Canadian heavy crude oil producer, specializes in extracting heavy oil from oil rigs using the SAGD process (Steam-Assisted Gravity Drainage). Founded in 1979, it is an integrated energy company involved in the oil and gas industry, producing petroleum, natural gas, petrochemicals, and related products.

The company employs over 16,000 people, making it a significant employer in the Canadian energy sector. It holds a prominent position in the energy market, particularly in synthetic crude production from oil sands. The company has a strong presence in North America, with operations in Western Canada and Colorado, and offshore drilling in Eastern Canada. It is also involved in offshore developments in the North Sea and conventional, land-based activites in Libya, Syria, and Trinidad and Tobago.

In this case study, we will explore how implementing KAIZEN™ methodologies led to significant lead time reduction, cost savings, and empowered project teams in heavy oil extraction projects.

The Challenge

Heavy oil extraction wells have a limited production life, resulting in declining production over time. To maintain production levels, new wells must be continually dug. However, the rising costs of delivering facility projects associated with SAGD wells has been a challenge for the company. The root causes were identified as follows:

Redundant Transfers and Rework

Redundant transfers and rework led to delays and increased costs in project delivery.

Siloed Deliverables Management

Poor cross-departmental collaboration and unclear supply chain interconnections led to inefficiencies and increased workload for specific departments.

Sporadic Deliverable Management

Since deliverables are managed only sporadically, issues are often detected only after they have already affected the budgets and timelines.

Excessive Buffer and Contingency Allowance

Project schedules contained excessive buffers and contingency allowances, leading to poor resource use and additional, unnecessary costs.

The Approach

To address these challenges and optimize project delivery, a comprehensive solution approach was implemented:

KAIZEN™ Events

KAIZEN™ Events workshops were set up with individual functional project teams to identify waste and non-value-added activities.

Improvement Suggestions

Over 200 improvement ideas were put forward by the teams and rated based on their impact on lead time reduction and ease of implementation.

Implementation and Guidance

The client has implemented the chosen improvements, ensuring proper tracking and support throughout the process.

The Results

The solution implementation yielded remarkable results for the company:

Empowered Functional Project Teams

As the project teams saw their suggestions being implemented, they felt more empowered and motivated. This enabled them to take a pivotal role in championing improvements throughout the company.

Lead Time Reduction

Over 200 improvement ideas were implemented, substantially reducing lead time for delivering well projects.

Significant Cost Savings

The value of a single day saved in project execution was estimated to be approximately $50,000. With these improvements, the project is set to save over $7.5 million per well on completion.

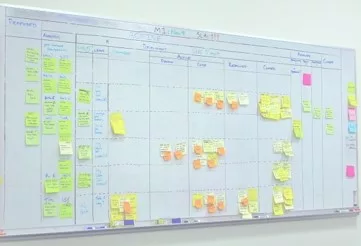

Sustained Improvement Practices

The company embraced a new way of executing projects, including developing a well project framework, establishing a project Obeya room, and enhancing project management skills to sustain the improvements.

Conclusion

In this case study, a major Western Canadian heavy oil producer faced challenges maintaining production levels and rising costs in SAGD oil rigs projects. By implementing the KAIZEN™ framework, the company reduced lead time, achieved significant cost savings – approximately $7.5 million per well – and empowered project teams. The sustained improvements included a new project execution approach, well design framework, and enhanced project management skills.