Problem

Our client, an upstream Oil & Gas producer, wanted to reduce overall project time to increase total project economics. A Kaizen team was brought in to work with discipline leads to map the process, identify and eliminate waste.

Root Causes

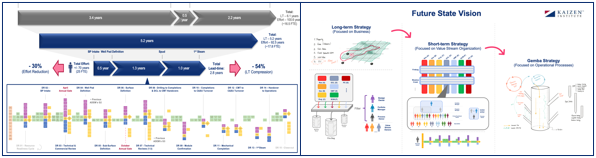

The client had a multi-disciplinary approach that carried excessive waste in schedule from task to task as different departments were engaged. It was difficult for client team members to gain an unbiased high-level view of the total process due to the complexity involved.

Solution approach

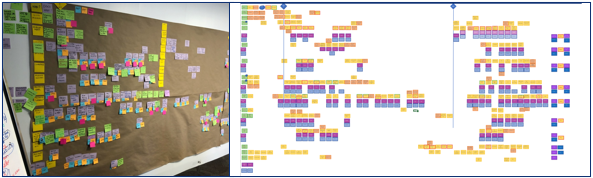

- Kaizen’s experienced team led a project mapping exercise in order to define the current state, identify waste and determine the ideal future state of the development process going forward.

- Engagement of client’s executive, leaders, employees used extensively.

- Time sensitive decisions made using lean Obeya principles.

Benefits

- Lead time of development reduced from by more than 50%

- Significant financial savings realized from:

- Employee time savings

- Sourcing savings

- Increased NPV due to capital savings and timeline reduction

See more on Construction

Find out more about transformation in this sector

See more on Project Management as a Service

Find out more about our services