The Challenge

Problem

In 2009, the company was near to closing its doors.

A number of problems contributed to the posting of negative results at the end of the year:

• Product quality issues: scrap index at 14%

• Delays in orders: production delay of 780 tonnes and special freight costs represented 20% of total transport costs

• High production costs: OEE from bottleneck equipment at 67% in an industry where energy is the major cost share

• Loss of 50% of the business

Root Causes

• Lack of basic stability

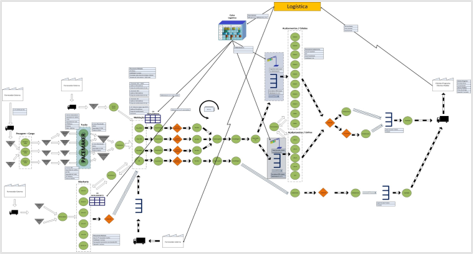

• Problems with communication amongst team members: each team had its own production plan and the impact of problems in one section was not projected through the value chain

• Lack of visibility of company results

• Little involvement of the CEO

The solution

Way from £7.4m to £30m Profit

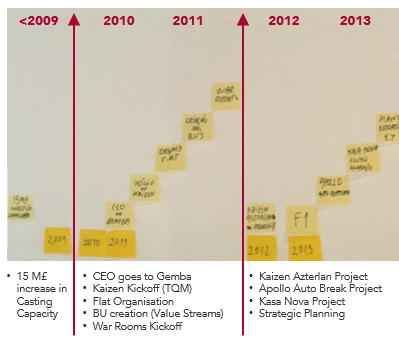

• KAIZEN™ Transformation Program (2009-2012)

• Breakthrough Hoshin Deployment based on Voice Of the Customer (2013-today)

• Organisation by Value Stream (“small companies”)

The Results

This transformation increased EBITDA by 150% in 6 years.

Sales (tonnes/year)

Sales increased by 20% each year.

Productivity (tonnes/man-year)

Productivity increased by 12.5% each year.

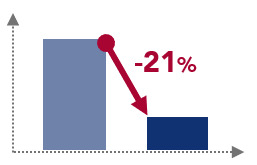

Scrap (ppm)

Scrap rate reduced by 21% each year.

#strategy #assemblymanufacturing

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Strategy & Leadership

Find out more about improving this business area