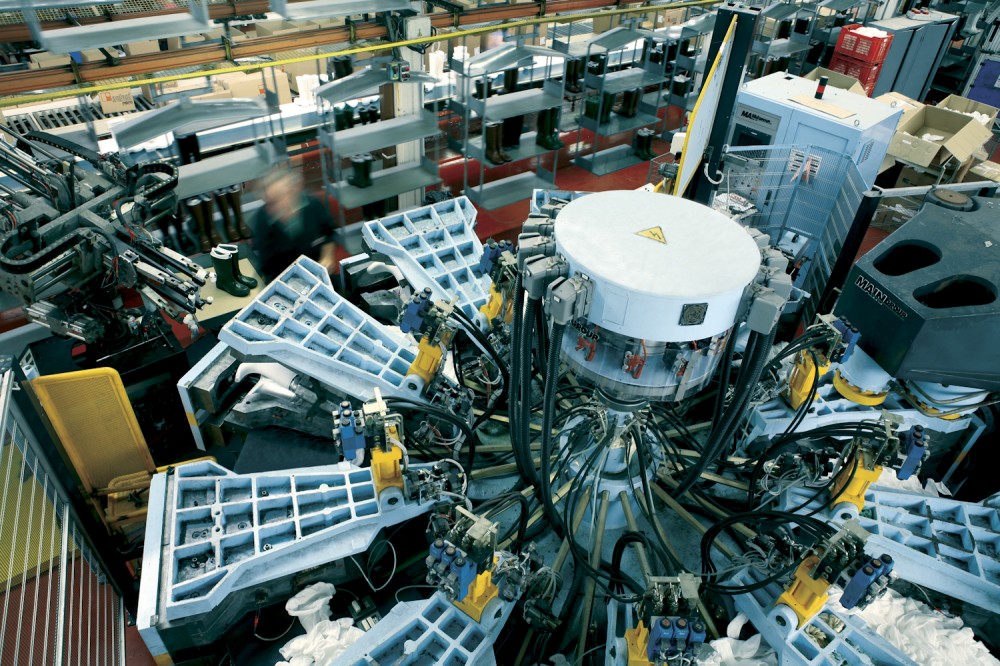

The Challenge

Problem

• Large investment in a New Plant (9M£ Capex)

• Very long Payback period (7 years)

• Investment on-hold

Root Causes

• New Plant Design very Expensive

• Traditional Supply Chain Design Principles

• Too much waste designed in

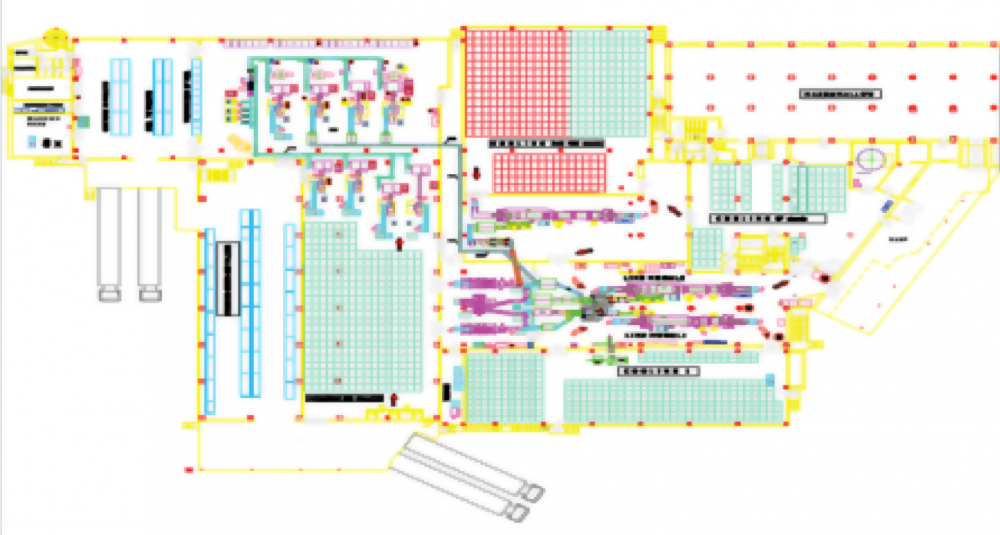

The solution

• Value Stream Design: Develop the entire value chain, aligned with the vision of the plant and Lean Principles

• Plant Layout Design: Reduction of waste in logistics, processes and communication circuit

• 8 layouts developed and evaluated against previously identified muda

• Direct Link between process and packaging

The Results

The optimal layout resulted in a reduction of project CAPEX of 12% (£7.9 million) and a payback period of 3,5 years.

Lead Time from purchase order to customer delivery

Delivery Lead Time decreased by 10% corresponding to less 2 days

Plant Capacity

Plant capacity increased by 25%

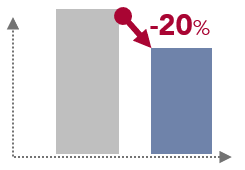

Total distance travelled

Total distance travelled decrease by 20%

#assembly manufacturing #process manufacturing #research and development

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Research & Development

Find out more about improving this business area