Many businesses and business leaders are sharing the view that one of the greatest threats to businesses worldwide is the growing challenges global supply chains are facing. Many Kaizen Institute clients confirm this stance.

Harvard Business Review concluded in an analysis that the Ukraine war, and the closer alignment of China and Russia, will continue to modify the exchange of energy, raw materials, industrial parts, and goods between the Western world and these two countries. This will most likely result in a growing interest in local supply chains, as already seen in industries such as Automotive.

Industry takes a hard look at the risks associated with international suppliers and considers buying more locally, even if this requires additional material price increases. Kaizen Institute’s take on current supply chain developments is that businesses are well-advised to consider applying the holistic and authentic KAIZEN™ principles and methodologies in their supply chains. (This may include switching to local supply chains as one of the options.)

A Lean supply chain that is more resilient during times of crisis as a Pull-System (demand-driven, Lean & Agile) reduces the risk of instability and variation in the value chain. The question is how a Lean system can be adopted to become more resilient.

Developing a supply chain digital twin model, based on an end-to-end strategic mapping exercise, provides visibility on the performance of all the elements and loops of the supply chain, including all the existing tiers of suppliers.

Applying the KAIZEN™ principle of visual management by establishing an obeya (mission control room), enables transparent risk and crisis management. To ensure immediate feedback during the crisis (and beyond), a Tiered Help Chain process is developed between all the teams engaged in the supply chain.

This Just-in-Time system with ”just-in-case” features is vastly superior to the traditional (but dissimilar) Push System with just-in-case” features. A resilient Lean system incorporates all the features of Toyota’s “Just-in-Time” system by creating flow in the logistics loops and protecting the whole value chain against crises and instability.

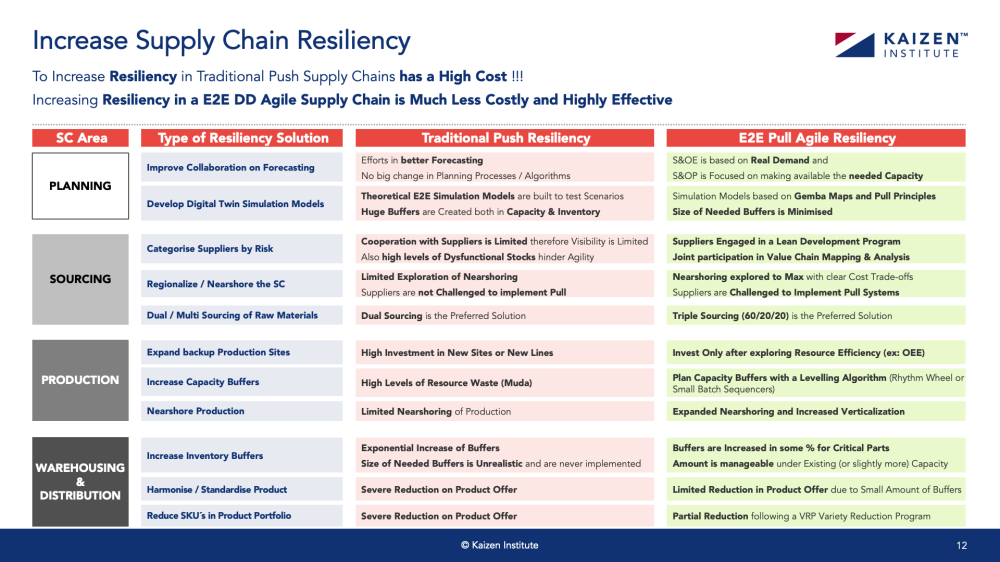

The following table explains the difference between a Traditional Push Value Chain and an End-to-End Pull (demand-driven), Lean & Agile Value Chain:

Kaizen Institute identifies real opportunities: creating, and continuously improving, a supply chain flow that is pulled by actual customer orders and resilient against crises (a true business continuity plan). A GEMBAKAIZEN™ Workshop is a viable way to get your supply chain improvements started, commencing with a strategic end-to-end value chain mapping exercise. To learn more, please contact our local KAIZEN™ experts in your country.