The Case

KAIZEN™ in Manufacturing started in 2018. Need to impact sales and profitability

- Stalled sales in the last 3 years

- Low profitability (EBITDA/sales) and with a tendency to decrease even more

- Most sales are in product and low margin segments (Construction)

- Lack of information on markets (size, quota, competition) and VOC

- Low efficiency marketing and commercial processes

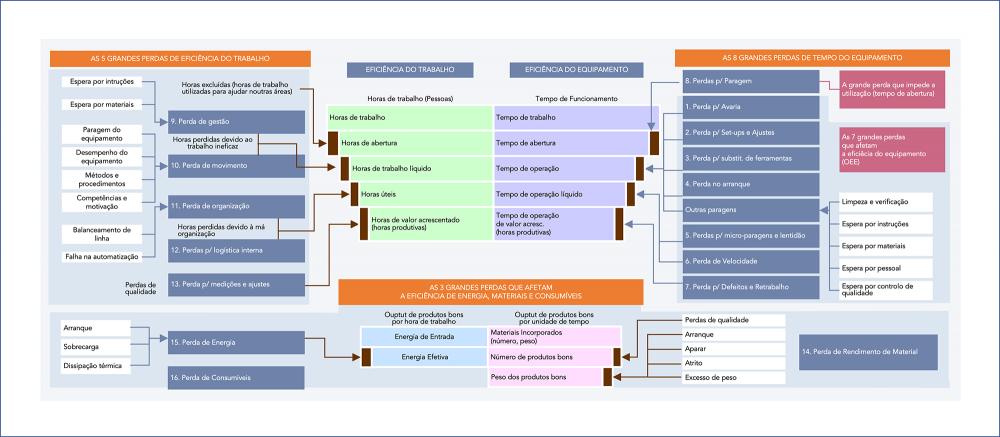

- Low production efficiency limits the effort to increase sales

The solution

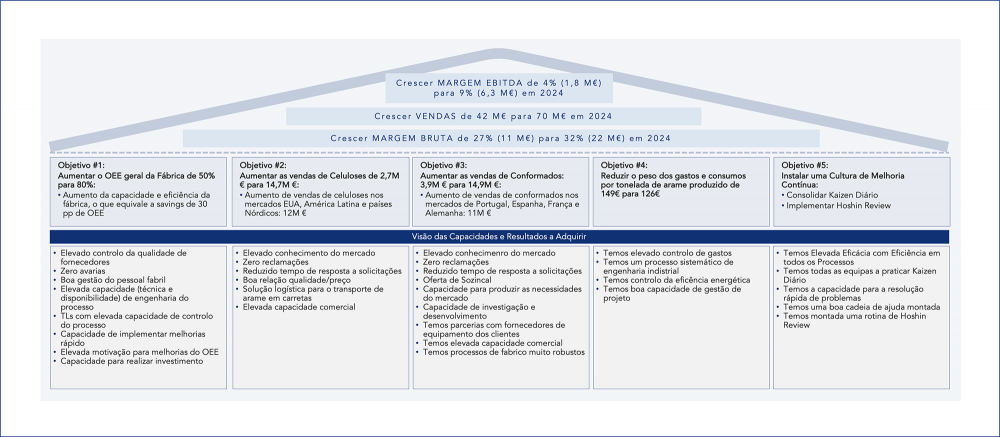

Strat to Action Plan (south of matrix X)… with 5 breakthrough priorities with goals

- Selection of breakthrough initiatives

- Market penetration (in 2 high margin/growth markets)

- Improving the OEE (on production lines for high margin markets)

- KAIZEN™ Culture consolidation (Deploy DK to all teams and implement Hoshin Review)

The Results

- Sales increase from 41 million to 65 million (59%)

- OEE increase from 50% to 80% (60%)

- EBITDA increase from 1,8 million to 4,9 million (172%)

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Strategy & Leadership

Find out more about improving this business area