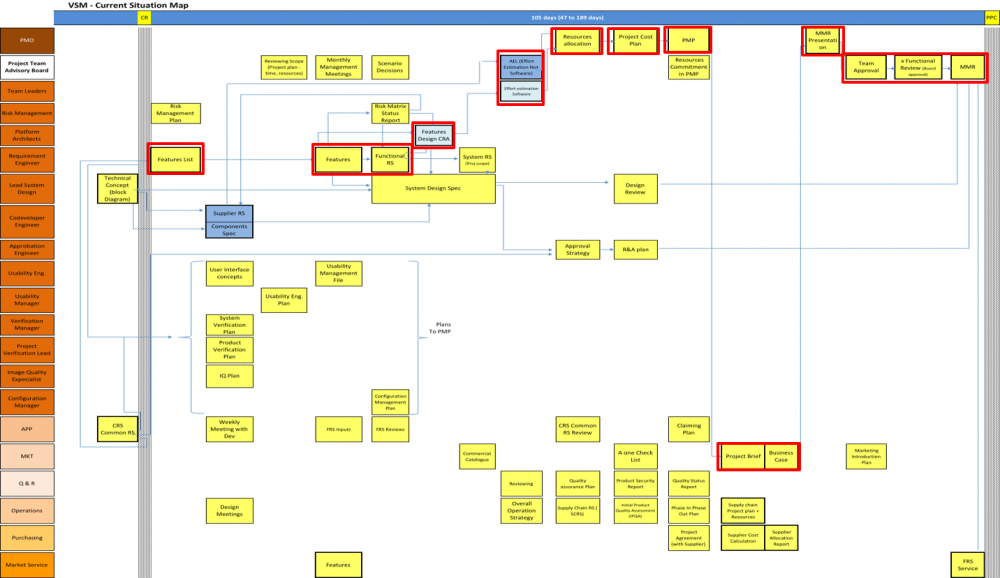

The Challenge

Problem

- Lengthy development lead time

- Last stage of the project plagued with rejects and rework

- Not enough development capacity

- Sales are not maximized by dropping customer requirements throughout the process

Root Causes

- Lack of communication between departments

- Rigid and bureaucratic process

- Development focus only on closed concept

- Inputs and exchanged requirements throughout the process

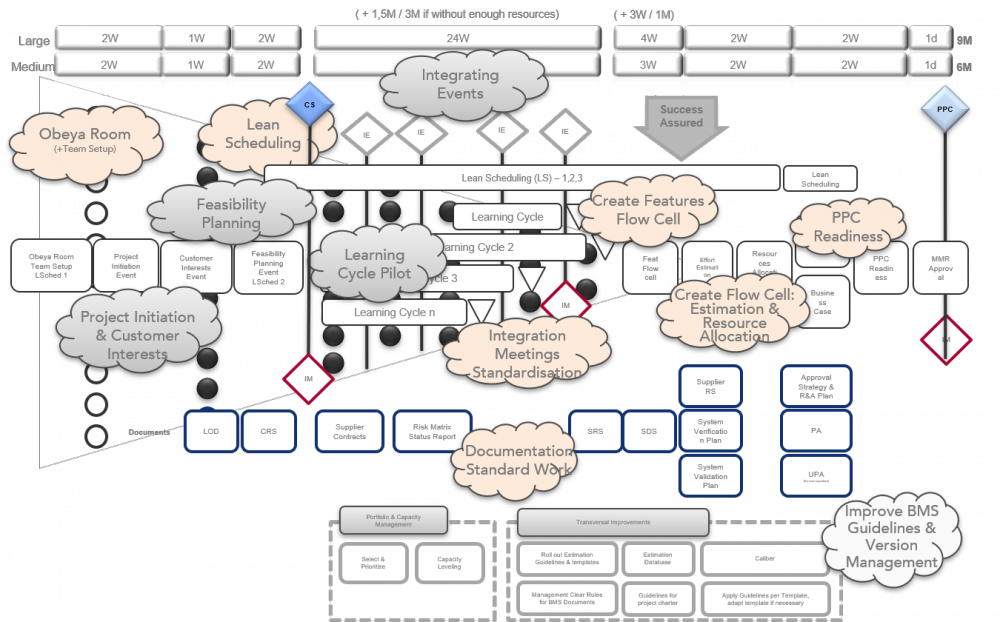

The Solution

• Obeya control and standardization of lean scheduling to increase communication

• Customer interests’ events, feasibility planning, learning cycles and integrating events to improve project quality

• Flow cells creation to reduce project lead time

• Documentation Standard Work to reduce project cost

The Results

The project had a payback period of less than 3 months with annual savings of £4.5 million.

Real Sales vs. Forecast Sales

Accuracy of sales forecast increased by 18%

Development Productivity

Development productivity increased by 8.6%

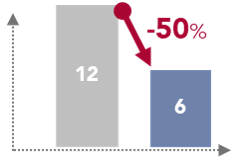

Project Lead Time

Project Lead Time reduced by 50%

#assembly manufacturing #operations

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Research & Development

Find out more about improving this business area