The Challenge

Problem

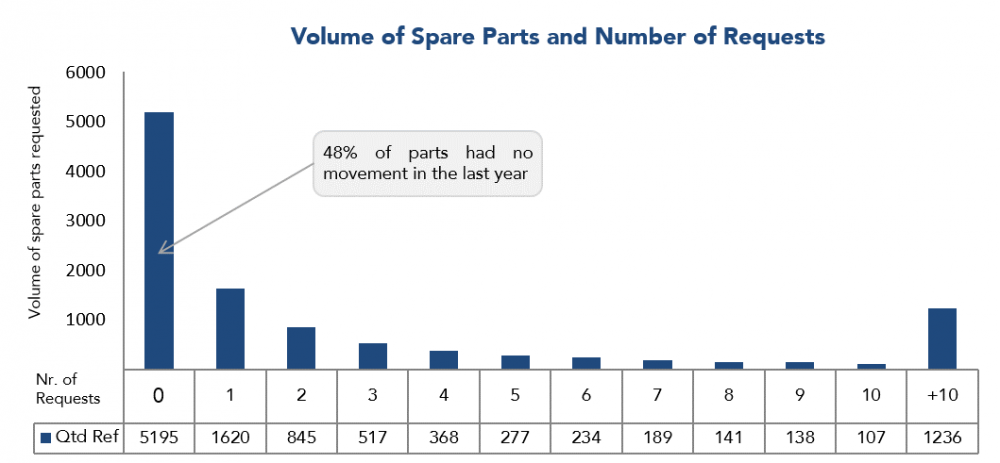

• 48% of stored spare parts were not consumed over the past year

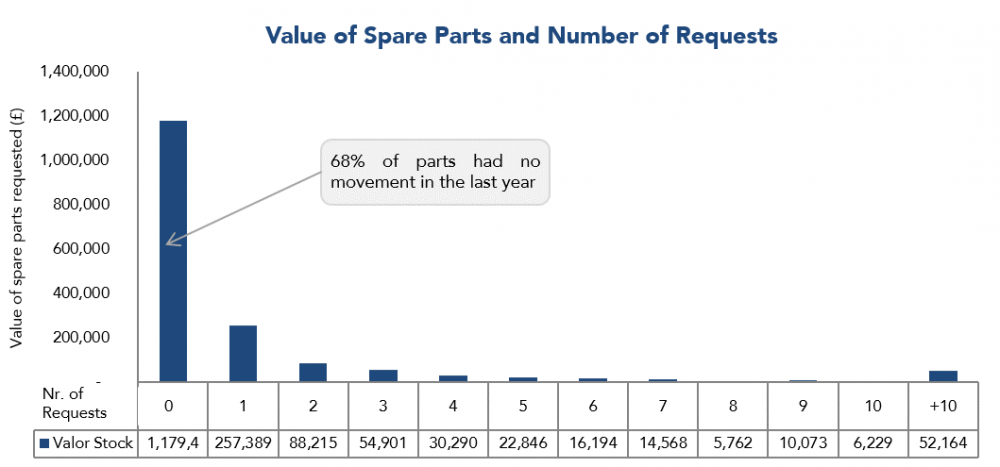

• 68% of the value of spare parts was not consumed over the past year

• 150 requisitions per day for spare parts

• 60% of spare parts have a supply lead time of 1 to 3 weeks

Root Causes

• Replenishment of spare parts done in an ad-hoc way, depending on experience and gut feeling

• Lack of structured information for stock analysis

• Low level of process automation contributed to errors

The Solution

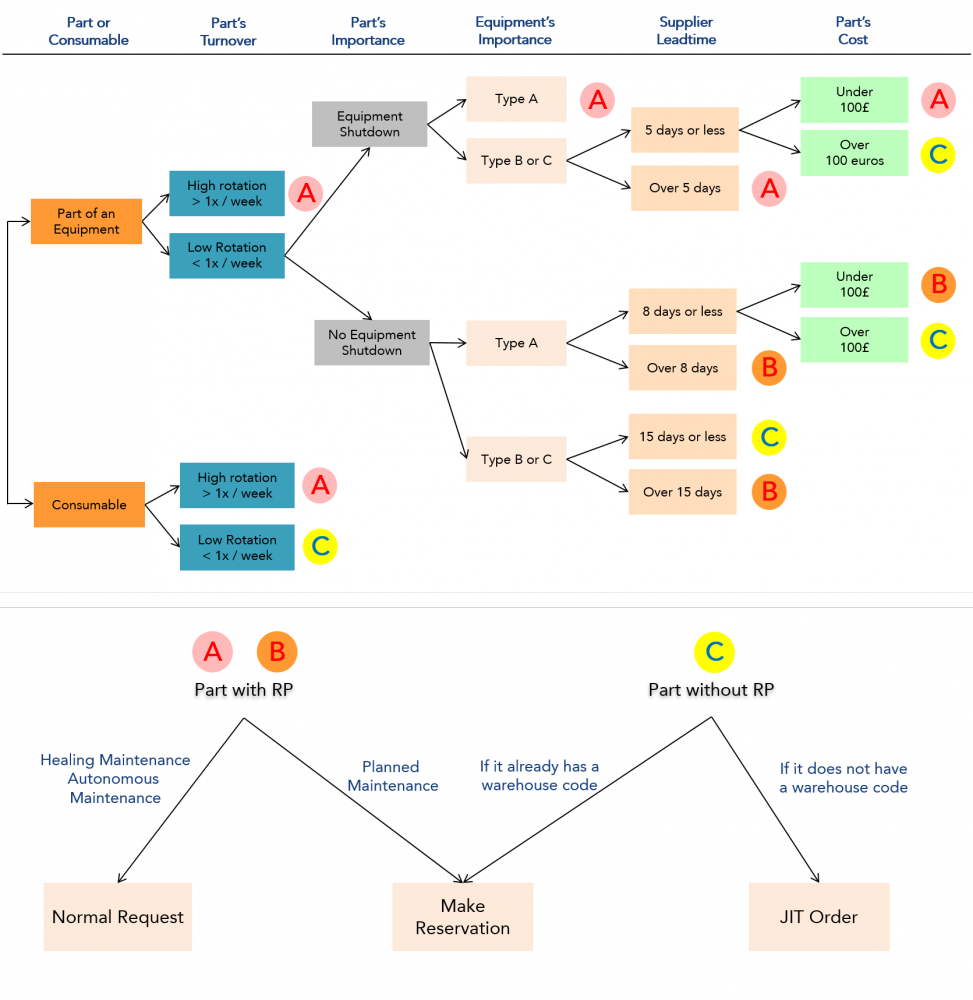

• Creation of an information structure that allows for parts classification according to criticality and consumption

• Implementation of replenishment levels for each part, to be updated automatically based on consumption from the last 36 months

• Implementation of safety stock to guarantee 99% parts service level

• Spare parts with low consumption are not managed through replenishment levels but through just-in-time ordering

• Study of suppliers to define the delivery lead times with precision

The Results

The organization was able to free more than £479,000 in cashflow.

Stock Value

The stock value of spare parts was reduced by 26%

#assembly manufacturing #process manufacturing #maintenance

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Maintenance

Find out more about improving this business area