Challenge

Problems

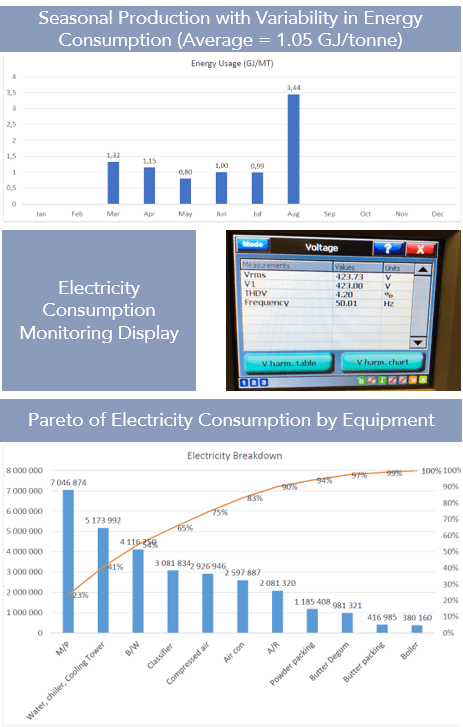

• High energy costs: 12% of industrial costs.

• Electricity costs increasing year on year.

Root causes

• Lack of knowledge of the weight of different equipment in the overall consumption.

• Unused equipment not switched off.

• Low factory power factor (0.85).

The solution

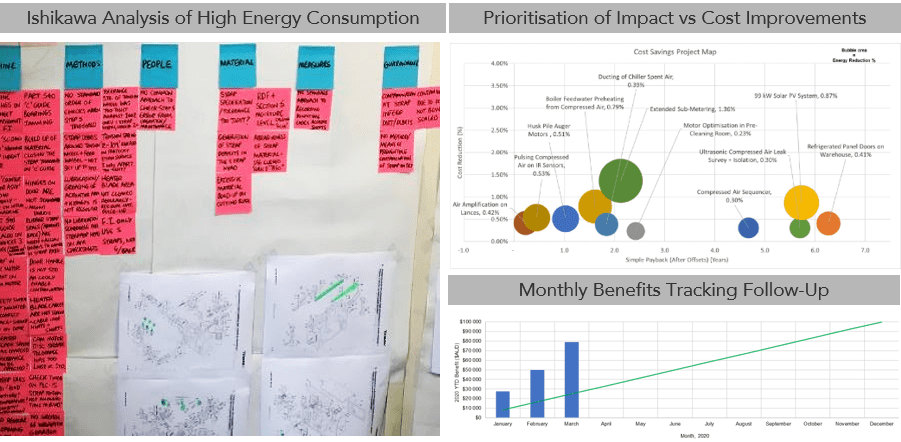

• Ishikawa analysis of electricity over-consumption.

• Process for disposal of unused equipment.

• Standardisation of start-up after shutdown, with optimum sequence to minimise power peaks.

• Installation of measuring devices on critical equipment. Consumption data analysis by equipment with launching of countermeasures.

The Results

This project generated savings of £211k/year.

Electricity Costs

Electricity Costs reduced by 17%.

Power Factor Correction

Power Factor Correction improved by 14%.

#process manufacturing #sustainability

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Sustainability

Find out more about improving this business area