The Challenge

Problem

- Finished goods inventory coverage of 15 days with a customer service level of 93% – dysfunctional inventory

- Raw materials and parts stock coverage of 30 days

- Between 1 and 5 days of WIP in production and assembly lines

- 50% of planned production lost due to lack of parts and poor line efficiency

Root Causes

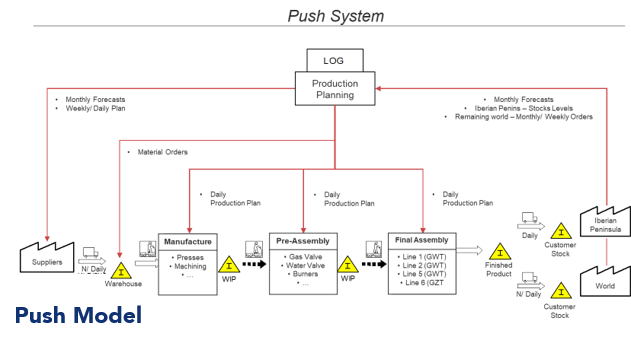

- Finished goods planning based on order forecasts: forecast errors between -18% and 16%

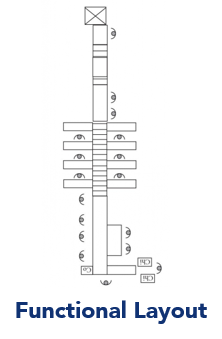

- Functional layout: preassembly lines separated from final assembly lines

- Operators isolated from each other, parts returned to the warehouse, supply of large pallet-sized containers, poor operator standard work, low line balancing efficiency

- Delivery to final assembly line by forklifts, under the instruction of operators or supervisors

The solution

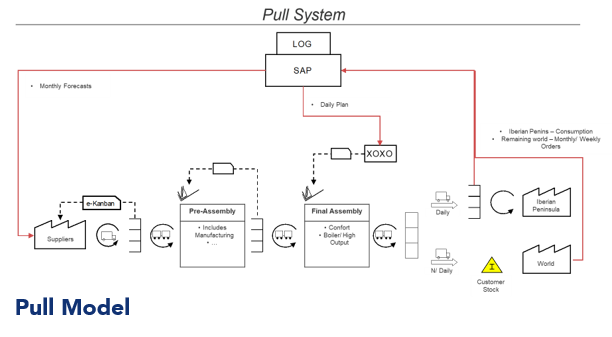

• Pull planning algorithm used on a daily basis to compare a certain replenishment level with the current stock of finished goods and create the production orders according to deviations

• Transformation of orders into KANBAN and planning on a daily basis through a logistics box

• Daily schedule determined by freezing one day of production according to levelling rules

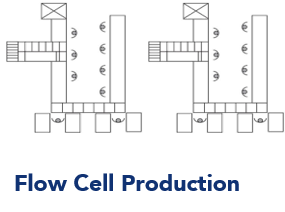

• Transformation of one assembly line to two with fewer product references on each; zero changeover time; balanced operation time between operators; small containers on the border of line

• Three Mizusumashi circuits for purchased parts, sub-assemblies and finished goods

The Results

The project had a Payback period of 5 months with annual savings surpassing £3 million.

Internal Defects

Number of rejected parts reduced by 52% (measured in parts per million)

Productivity

Number of parts produced by each operator increased by 36% (on average)

Inventory Coverage

Finished goods stock coverage reduced from 50 days to 30

#assembly manufacturing #operations

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Operations

Find out more about improving this business area