The Challenge

Problem

• Low productivity amongst warehouse teams

• Suboptimal occupation of storage slots

• Unshipped lines or picking errors

• No vacancies to absorb new storage SKUs

Root Causes

• Poor visual management to support material flow

• Storage slots not adjusted to specific needs of parts

• Poor planning of team activities

The solution

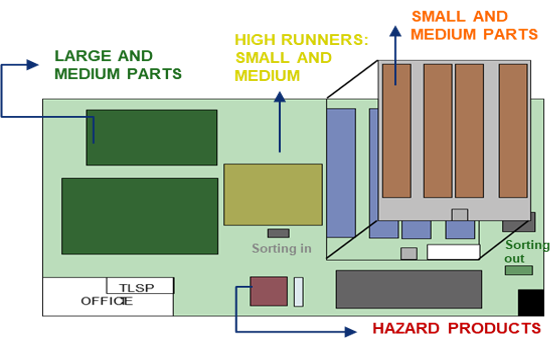

• Sorting of parts on arrival according to size and storage area: small parts on mobile shelves; medium parts on trolleys; large parts on pallets

• Cross docking for parts to be shipped on the next working day

• Mizusumashi route to move storage trolleys, shelves and pallets to their future storage area/aisle

• Customised storage slots for each part: this allowed for high density of parts in warehouse

• Planning and balancing of workload through Daily KAIZEN™ and levelling box

The Results

The project had a Payback period of 3 months with annual savings of £207,000.

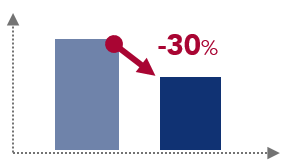

Warehouse space

Amount of warehouse space required reduced by 30%

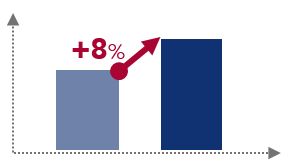

Productivity

Warehouse team productivity increased by 8%

#logistics #warehousing and transport

See more on Logistics

Find out more about transformation in this sector

See more on Warehousing & Transport

Find out more about improving this business area