The Challenge

Problem

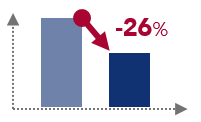

• Breakdown Maintenance losses of 14.7 hours/month

• Total duration of planned stoppages over the course of one year was 168.1 hours

• Average setup time of 74 min

• Quality losses of 9.15%

Root Causes

• Lack of information on unplanned stoppages and ad-hoc resolution of problems

• Performance losses due to lack of standard parameters for production

• Inefficient planned stoppages due to poor diagnosis, lack of resource allocation, material preparation and team coordination

• Micro-stoppages in paper transformation and undefined setup activities

• Suboptimal planning sequences

The Solution

• Structured Problem-Solving approach for unplanned stoppages, supported by detailed data

• Definition of optimal production parameters

• Standardized procedures and operators training

• More frequent planned stoppages managed through project management tools such as Last Planner, Risk Analysis and Task Kanban

• Autonomous maintenance to reduce micro-stoppages during paper transformation

• Production sequencing guidelines and process standardization to minimize setup activities

The Results

The project had a payback period of 4 months with annual savings surpassing £1,7 million.

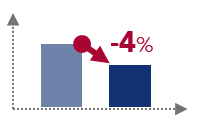

Breakdown

As a result of maintenance issues, breakdown times reduced by 20%

Planned Stoppages

Time for planned stoppages reduced by 26%

Quality losses

Volume of quality losses reduced by 4%

Setup Time

Logistics productivity increase by 31% with optimization of layouts and containers

#assembly manufacturing #process manufacturing #maintenance

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Operations

Find out more about improving this business area