Challenge

Problems

- Most projects completed with delays

- High development costs

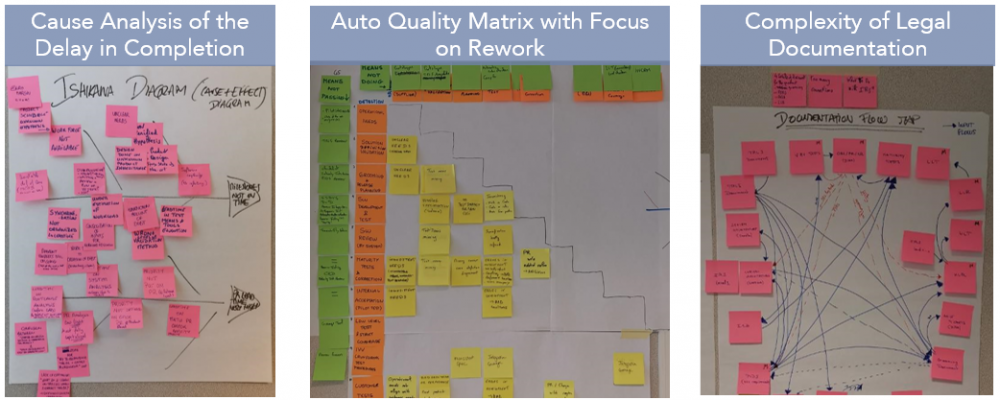

Root causes

- Rework at advanced stages of development due to design problems

- High complexity and redundancy of the legal documentation process

- Communication failures between system teams (define the solution) and software (implement the solution)

- Tests carried out at an advanced stage of development, not allowing agile correction of bugs found

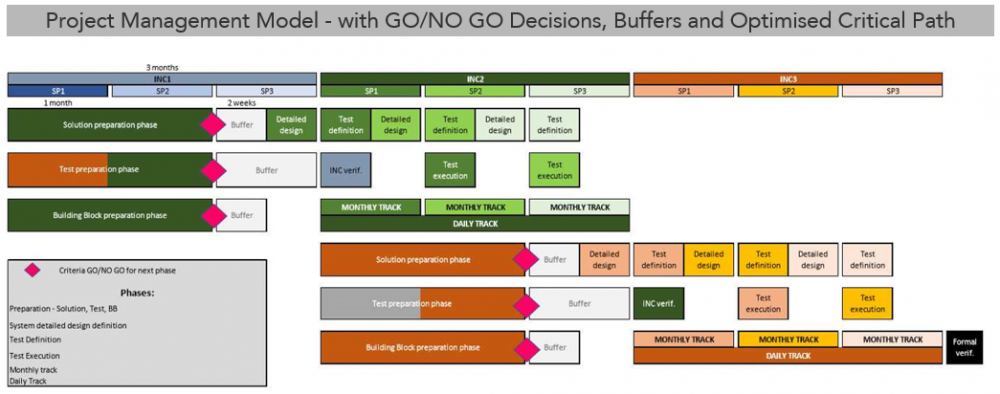

The solution

- Parallel design/preparation phases, allowing co-engineering sessions: a multidisciplinary team that defines and implements the solution

- Go/No Go criteria ensure alignment between different project phases

- Synchronization of all the teams involved, to ensure the follow-up of the process, with defined pacing

- Daily follow-up of problems detected during testing and correction (continuous integration)

The Results

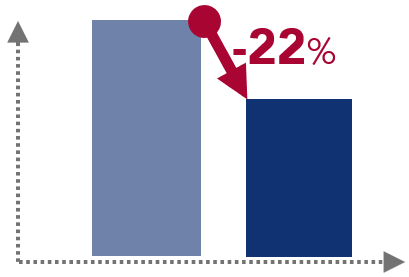

Development Effort (Man.Days)

Development efforts reduced by 22%.

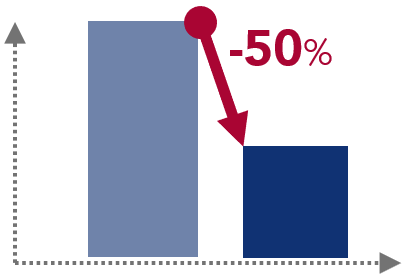

Project Lead Time

Project lead time reduced by 50%.

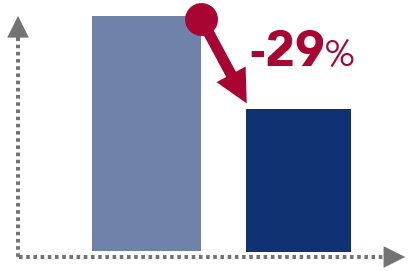

Time Spent on Documentation

Time spent on documentation reduced by 29%.

#assembly manufacturing #process manufacturing #research and development

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Research & Development

Find out more about improving this business area