The Challenge

Problem

- Operational costs on an upward trajectory in the transport business

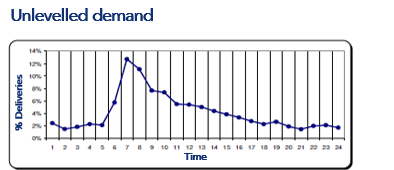

- Unlevelled demand throughout operational hours: 50% of the demand within a 4h period (out of 24h)

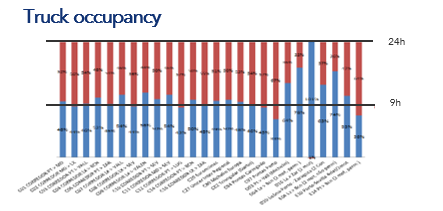

- High percentage of inactive time for vehicles and drivers

- Pressure to reduce operational costs in order to hold market share

Root Causes

- Traditional Transport System Design: resources dedicated to different groups with fixed capacity that does not contribute to an improvement in resource occupation

- Lack of resource planning standards: daily reactive management

- Excessive loading and unloading times: high percentage of non-value-added tasks

- Increasing fuel and resource cost

The Solution

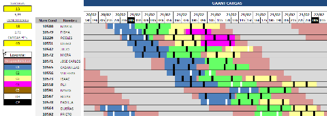

• Separating trailer planning from driver and truck planning: intermediate terminals to break routes and reduce empty trailer trips

• Resources dedicated to geographical regions instead of groups allows for improved occupation

• Implementation of Planning Tools in loading area, delivery area and capacity scaling. 80% completion of routes planned days in advance, with daily optimisation for the remaining 20%

• Productivity improvement of load/delivery operations supported by Daily KAIZEN™ Tools

The Results

The project had a Payback period of 7 months with annual savings surpassing £2.5 million.

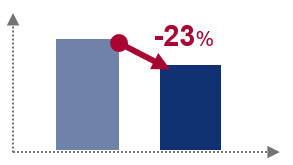

Cost per load

Cost per load reduced by 23%

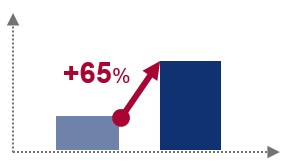

Load/Unload Productivity

Number of loading and unloading activities increased by 65%

#logistics #warehousing and transport #analytics

See more on Logistics

Find out more about transformation in this sector

See more on Warehousing & Transport

Find out more about improving this business area