The Challenge

Breakthrough KAIZEN™ Audit

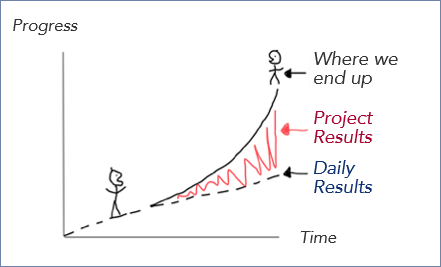

Project vs Daily Improvement Vision

Problem

• Variability in achieved results between similar projects

• Inability to unblock projects due to decision-making dependency

• Lack of communication of solutions implemented and results obtained

Root Causes

• Different project approach according to different leaders

The solution

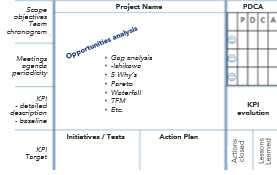

Standard Project Board

Portfolio Benefit Tracking

• Structured improvement sprints with 6-month cycles for planning, design of solutions and implementation. Between each phase and during the implementation, status updates with top management are organised. Implementation is followed by one year of monitoring

• Standard Project Board guides project teams through a standard implementation approach and serves as a communication tool to all stakeholders

• Project Portfolio Benefit Tracking brings together all ongoing projects for a visual check on KPI results and aids in decision making

The Results

The projects implemented have generated annual savings of £300,000.

#assembly manufacturing #operations

See more on Process Manufacturing

Find out more about transformation in this sector

See more on Improvement Projects

Find out more about improving this business area