The Challenge

Problem

• Average stock coverage of 67 days, with average supplier Lead Time of 31 days

• £18.1m worth of inventory held in stock due to inconsistent deliveries by the supplier

• 4000 pallets stored in the warehouse

Root Causes

• Lack of frequent KPI tracking: stock value, stock coverage or supplier Lead Time

• Component ordering based on forecasts with low accuracy

• No repercussions for suppliers who fail to comply with service level agreements

The Solution

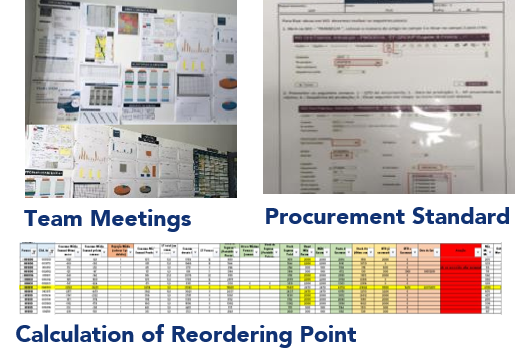

• Implementation of Periodic ABC Classification (frequency and volume) to identify Material Requirement Planning and Reorder Point articles

• Reorder Point Pilot Tool in Excel to validate the concept

• Renegotiation of supplier contracts: Lead Times, frequency of delivery, minimum order quantity, consignment and packaging

• Pull Planning Manual and Standardisation of planning processes

• Standard Reports to communicate with suppliers

The Results

The organisation was able to free more than £2.3 million in Cashflow.

#assembly manufacturing #sourcing

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Sourcing & Suppliers

Find out more about improving this business area