The Company

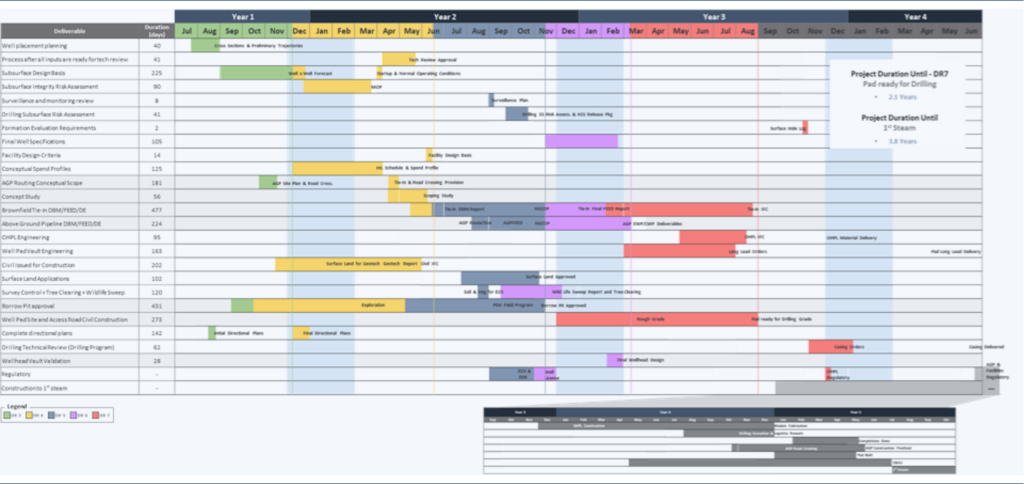

This company, a Canadian energy producer and supplier, has been in operation for over a century. Specializing in producing synthetic oil from oil sands, the company supplies high-performance oils, primarily to the North American market. It operates using two extraction methods: In-situ production and Open-pit mining. Approximately 80% of Canada’s oil sands are too deep, demanding the use of in-situ production, a three-stage process involving drilling, steam injection, and extraction of bitumen to the surface. These In-Situ techniques require using well pads. The company’s long-term plan set out to develop 3 well pads each year.

The Challenge

The challenge faced by the team centered on improving the management of the well pad development project. The initial situation presented a series of challenges, particularly:

- A resource efficiency paradigm instead of flow efficiency;

- Absence of clarity in inputs/outputs for other departments;

- An inefficient approval process without defined requirements;

- Rework due to design and scope changes at any time;

- New technology tests were carried out on the critical development path.

The Solution

The company implemented a set of solutions to overcome the challenges identified in managing the well pad development project. These solutions were designed to address the previously identified gaps and improve the overall process efficiency. Here are the main solutions implemented:

Flow Efficiency Paradigm

The team replaced the resource efficiency paradigm with the new flow efficiency paradigm, prioritizing flow in all project phases.

Work Packages with Clear Inputs/Outputs

Work packages with clearly defined inputs and outputs were established. This reduced ambiguity and ensured that each team clearly understood the tasks to be performed and the deliverables to be developed.

Efficient Decision Reviews (DR’s) to Minimize Rework

An efficient decision review process was implemented, aiming to minimize rework. These reviews were structured to ensure clear compliance with requirements and reduce future issues.

Design/Scope Freeze during Decision Reviews (DRs)

A proactive approach was adopted with the freezing of design and scope during the DRs. This brought stability to the process, avoiding changes that could result in costly rework activities.

Design Standardization

The design process was standardized to embed best practices and reduce process variability.

Introduction of Mura Well Pads for Testing New Technologies

The creation of Mura Well Pads provided a dedicated environment to test new technologies. This allowed the team to assess innovations without disrupting the critical development path, mitigating risks and ensuring project continuity.

These were the leading strategic solutions implemented by the team to improve on the opportunities identified during the initial situation analysis phase.

Results

Implementing the above-described solutions resulted in significant benefits, showing the positive impact of the changes implemented in the well pad development process.

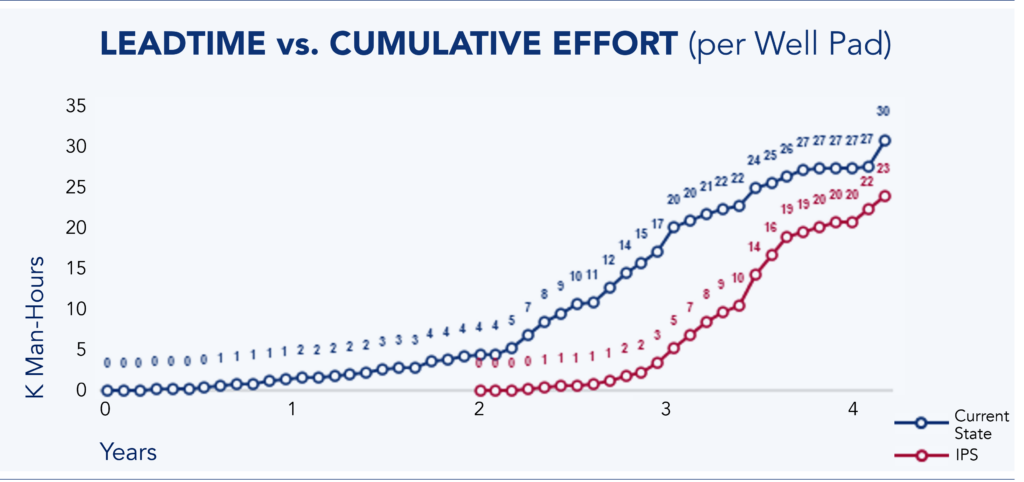

The improvement in planning, workflow optimization, and implementation of more efficient practices contributed to a 47% reduction in the total project execution time. This improvement represents a significant acceleration in the project lifecycle. The implemented improvements also allowed for better resource utilization, resulting in a 23% reduction in total effort. Finally, implementing new project management practices led to a 10% reduction in total costs.

The gains in efficiency and cost reduction resulted in an annual saving of 1.95 million Canadian dollars for the company. These benefits result from successfully implementing the proposed solutions, showing benefits in terms of time, effort, costs, and revenue.

See more on Capital Project Excellence

Find out more about improving this business area